As I mentioned in my previous post I've been working an a whole bunch more wagons one of which will require the upper part to be made by hand as it is too fine to 3D print. Specifically I'm working on a Rhosydd slate quarry rubbish wagon using a drawing from the Lewis and Denton book. This wagon has a wooden underframe very similar to the slab wagons with a three sided iron body to hold the waste. Unfortunately I can't find a photo that I can show you of a complete Rhosydd rubbish wagon, but you can get the general idea from this photo, while a photo part way down this page shows a rusting upper body.

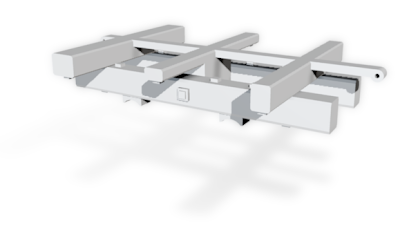

So far I've generated the 3D model for the underframe as you can see from this render. The wheels will attach in the same was as the slab wagon using axle retaining clips.

I haven't ordered a test print yet as I'm going to wait and order prints of all the wagons I'm currently working on at once, but I'm not expecting any issues given how similar to the slab wagon the model is. Having said that I'm not as confident about producing the upper body, although I have now made the first prototype.

The reason I can't print the entire model is that the minimum wall thickness for the material I'm using is 0.3mm. Walls that thin though are quite brittle, and as 0.3mm represents approximately an inch at 4mm to the foot scale, it would obviously produce walls that were too thick to represent sheet metal. I'm intending to solve this problem by modelling the sheet metal using ... sheet metal.

The photos show the progression from raw materials to the assembled prototype. Essentially I draw out a pattern on the computer based on how I wanted to fold up a single piece of metal to form the body (minus the rivet details). A printed copy of the pattern was then stuck to a sheet of 0.12mm brass before being carefully cut out using scissors; the tin snips unfortunately have serrated blades meaning that they aren't any use as they leave crinkled edges on the metal, although they are good for cutting sheet sections etc. a cheap non-serrated set are now on order. The fold lines were then scored using a scalpel and then any remaining paper was peeled off and the metal cleaned to remove the glue.

The upper body was then formed using my hold-and-fold. I was going to simply glue the corners but I'd not taken the thickness of the sheet into account when designing the pattern so had to resort to soldering to keep the corners together. Soldering was fairly straight forward; I tinned one side then held the joint closed with a bulldog clip before applying the soldering iron. As the solder in the gap melted the clip pulled the corner tight and once cool left me with a nice join that just need a little filing.

The result is pretty good. It isn't an exact replica as the original is made of angle iron with separate sheets for each face but once I've added rivet detail and filled the body with some rubbish it should look pretty good. I'll tweak the pattern slightly to take the material thickness into account and make up another one and then add some rivets before painting. When I eventuall get the underframe printed I should just be able to stick the two halves together.

For my first attempt at designing and building my own model from sheet brass, and my first ever attempt at soldering brass sheet I'm really happy with how it's gone so far.

Now that's an interesting little project, and there's nothing better than sheet metal to represent sheet metal. You could always design an etch for the upper!

ReplyDeleteFor scribing fold lines in brass I use a scrawker, which is a tool with a hook like 'V' shaped blade used for scribing plasticard. Both Olfa and Tamiya make them. My 'snips are Draper Expert jewelry snips, good quality and not too expensive.

When I saw the drawing I thought it was the perfect little project to experiment with using brass sheet, as the upper isn't too complicated.

DeleteI had wondered about etching, and when I've got the design right I'd certainly be interested in giving it a try. Any suggestions on companies that do small scale etching? Many of the ones I've looked at want A5 or A4 sheets which is a little excessive, especially for a test etch of one of these wagons.

I always find PPD in Lochgilphead are not to be beaten on price or service, although they have a minimum width of 280mm, but I find that they are more than helpful if you talk to them on the phone. I use Adobe Illustrator, but they accept Corel and other software. http://www.ppdltd.com/www/page_1_intro.html

ReplyDeleteThe wagon body is looking great, and as Paul says, nothing better than metal for replicating metal. I'm afraid there's nothing much else of rolling stock interest in the Lewis and Denton book, although there are plans of a mobile rail bender and of course the "megryn" incline carriages etc. Just ask if you want more scans. I would send you the book, but it is like gold dust and don't want to risk it in the post or with parcelfarce!

Will you be using the Archer Rivets on the body?

Ah yes, looking again at the PPD website I see they are flexible on the size, the A5 and A4 sizing being just to give cost examples. I have a few other ideas of things I'd like to try so I'll probably test out the patterns as I've done with this wagon to iron out obvious problems and then do a test sheet containing a few parts, and then maybe an A5 sheet per model or something so I have plenty and can give/sell some as well.

DeleteI've picked up a copy of the Slate Quarry Album so have lots of drawings and photos to be working from for quite a while, so definitely don't even think about risking the Lewis and Denton book in the post. On that topic does anyone know of other books with plenty of scale drawings of narrow gauge wagons (preferably something a little less Welsh)?

I did think about trying to punch out the rivets but given that in most areas I need rivet heads on both sides of the metal, and they are tiny, then yes it will be more Archer rivets, but I'll wait until the 2nd prototype that will have better corners before adding the rivets given how expensive, relatively, they are.

Aha! That book is a gem! Good call, getting hold of that. I was going to suggest, if you were thinking of selling the kits, that you could step them up on a sheet for economy. The rivets could be half-etched, too (or rather the body round about. Fold lines could be half-etched on the rear of the sheet. You probably already thought of that, sorry!

DeleteJames Boyd's books have marvellous drawings...also back-numbers of the "Narrow Gauge and Industrial Review"...I think there is an index on the 'net. There was a nice little Oakwood volume on the Leek and Manifold with good drawings, I think my Father-in-Law has the later, big book, he might let me scan some of the plans. I think there are titles about the Snailbeach and the L&B available with drawings, but they are a bit pricey. Sorry I don't have any English mining books :-( so many mines, so little time...

Slate Quarry Album is indeed superb - and much sought after judging by second hand prices! There are odd drawings in back copies of Industrial Railway Record, have a look at the Industial Railway Society's website as some of the older IRRs have been scanned and published in their on-line archive.

DeleteIain, when you've used PPD have you gone for the black/white/red/blue layered approach or have you produced black and white images for the front and the back? My preference for vector images would be SVG which technically doesn't support layers and isn't in there list of supported formats, although I could easily export as PDF which they seem to accept. I had thought about etching the rivets (the fold lines would definitely be half etched) but the problem is that they need to appear on both sides of the same piece of metal in some places and I can't really half-etch from both sides and expect a solid model!

DeletePaul, yes some of the prices for the slate quarry album are absurd. I managed to grab a copy for £20 including P&P which I didn't think was too bad, especially as it is in mint condition -- unlikely to last like that on my workbench for long. Thanks for suggesting Industrial Railway Record, I didn't know that some of the older ones had been scanned but a trawl through there for interesting drawings sounds like a fun way of passing the time.

Yes, I always use black, blue and red on different layers..have a chat to them, they are very helpful and I am sure that you can come to an arrangement about the software. I see what you mean about the half-etching and the rivets...I should have realised!

ReplyDeleteThanks Iain. I'm going to put together a simple test showing how I would draw things given their instructions and then contact them for advice before drawing up the final etch as it doesn't seem to make sense to spend lots of time producing an etch with multiple things on it if my way of working doesn't work for them.

DeleteBack to etching - should you go down that route and include half-etched dimples for rivets its good practice to etch some extra dimples on an area of waste etch. This gives you somewhere to practice punching out rivets (and set up any riveting tools used) before starting on the body itself.

ReplyDeleteThat is a clever idea that I hadn't thought of, thanks! I'm currently in two minds about etching though. The problem is that I think the metal is too thin for half-etch fold lines. On my second attempt I scored the material to help with the folding, but obviously slightly too much and it cracked when folded. I'm guessing the same would happen with a half-etch line.

Delete