Not long after I started building Canopus I was warned by a fellow modeller that when originally released there was an issue with the slide bars. Essentially in the original kit the slide bars were so close to the coupling rods that there wasn't enough clearance for the crosshead to slide along the bars. Given that a number of changes have been made to the kit since it was released (different, wheels, motors and gears) I was hoping that the problem had been fixed. Unfortunately it seems not.

As you can see in the photo the slide bars are so close to the frames that the filed down retaining nut actually forces them outwards. This means I'm going to have to make some alterations to the part to move the slide bars out a little bit on each side to provide enough clearance. While the slide bars don't fit properly they did highlight that I'd managed to get the cylinder bracket on wonky which I've now fixed, hence the rubbed off paint on the bottom bracket in the photo.

Fortunately I have a copy of an article from the September 2006 issue of 009 News where Phil Savage documented how he went about altering the slide bars. He also hit a problem with them being two short and the crosshead striking the support bracket on the back-stroke. Looking at photos of his completed model though, it looks like he ended up with the cylinders and slide bars being perfectly horizontal while they should be on an angle and I'm wondering if that would change the distance of travel. I'll have to assemble the crossheads before I can see if my model suffers from this second issue as well.

Sunday, November 30, 2014

Saturday, November 22, 2014

Painted Sheds

Having been side tracked by building some OO9 gauge track, I've finally gone back and painted the two N gauge sheds built from the Severn Models kit. Both models involved me trying a new technique in their painting.

I painted the walls and door of the wooden shed using my standard approach for aged wood which has worked well on the OO9 wagons I've recently been building. This seems to work well for N gauge buildings as well. When it came to the roof, however, I wasn't happy with the very flat look of painted brass. To add a little texture I painted it with RailMatch roof dirt and then blew on a small amount of polyfilla while the paint was still wet. Once the paint had dried I then painted it again to cover the white plaster. This seems to have given a nice surface, although I don't think the same would work in 4mm scale as the texture would still be fairly smooth.

I've never tried painting red brick before and the second shed caused quite a few problems. I tried a number of different approaches before I settled on something that mostly worked. In the end I painted the walls with RailMatch dark brick, and then used thinned down RailMatch weathered stone run into the mortar gaps. A final patchy black wash made things look nice and dirty. The corrugated roof was initially painted with roof dirt before a dry brushing of Model Color London grey. This gave a nice approximation of new corrugated tin which was then aged using repeated applications of MIG Productions standard rust effects.

While I did enjoy building and painting these sheds, the slight detour back to N gauge modelling has confirmed that I'm much happier working at 4mm to the foot scale so I don't think I'll be returning to N gauge at any future point.

I painted the walls and door of the wooden shed using my standard approach for aged wood which has worked well on the OO9 wagons I've recently been building. This seems to work well for N gauge buildings as well. When it came to the roof, however, I wasn't happy with the very flat look of painted brass. To add a little texture I painted it with RailMatch roof dirt and then blew on a small amount of polyfilla while the paint was still wet. Once the paint had dried I then painted it again to cover the white plaster. This seems to have given a nice surface, although I don't think the same would work in 4mm scale as the texture would still be fairly smooth.

I've never tried painting red brick before and the second shed caused quite a few problems. I tried a number of different approaches before I settled on something that mostly worked. In the end I painted the walls with RailMatch dark brick, and then used thinned down RailMatch weathered stone run into the mortar gaps. A final patchy black wash made things look nice and dirty. The corrugated roof was initially painted with roof dirt before a dry brushing of Model Color London grey. This gave a nice approximation of new corrugated tin which was then aged using repeated applications of MIG Productions standard rust effects.

While I did enjoy building and painting these sheds, the slight detour back to N gauge modelling has confirmed that I'm much happier working at 4mm to the foot scale so I don't think I'll be returning to N gauge at any future point.

Wednesday, November 19, 2014

Track Painting

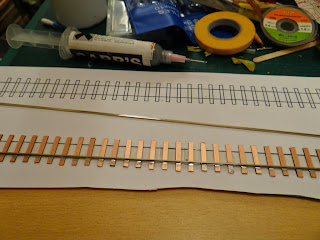

While I was more than happy with my first attempt at track building clearly it needed painting as sleepers are never copper coloured and the rail is never that shiny.

The first job though was to fill the gaps I'd had to file in the sleepers and I did this using some perfect plastic putty from Deluxe Materials which was filed smooth once it had set. The rails were then given a good clean before I tried something new; metal black.

When I built Jerusalem I painted the rails but it wasn't exactly a success. I found that the paint wouldn't stick well to the rails and tended to flake off over time. This time I decided to try using a chemical to blacken the rails instead, specifically I'm using Carr's metal black for nickel silver which I picked up from C&L Finescale along with the track. The health warnings on the bottle were almost enough to put me off using it, but I gently applied it to the rail using cotton wool buds. I was amazed just how quickly it works, but you do have to make sure the rail is very clean as I found any bits that weren’t were impervious to the chemical and stayed shiny. Once I was happy with the colouring I then applied some Carr's Electrofix to seal everything. Electrofix has a misleading name in that it doesn't actually conduct electricity, so I then buffed the railtops using a coffee stirrer which removed the electrofix and some of the blackening to give a used look to the rails. The final step was to paint the sleepers which I did using RailMatch sleeper grime.

Amazingly after all that the rails still conduct power nicely and the locomotive still moves, and I think the whole thing looks much more convincing than the ready-to-run track I was using before.

The first job though was to fill the gaps I'd had to file in the sleepers and I did this using some perfect plastic putty from Deluxe Materials which was filed smooth once it had set. The rails were then given a good clean before I tried something new; metal black.

When I built Jerusalem I painted the rails but it wasn't exactly a success. I found that the paint wouldn't stick well to the rails and tended to flake off over time. This time I decided to try using a chemical to blacken the rails instead, specifically I'm using Carr's metal black for nickel silver which I picked up from C&L Finescale along with the track. The health warnings on the bottle were almost enough to put me off using it, but I gently applied it to the rail using cotton wool buds. I was amazed just how quickly it works, but you do have to make sure the rail is very clean as I found any bits that weren’t were impervious to the chemical and stayed shiny. Once I was happy with the colouring I then applied some Carr's Electrofix to seal everything. Electrofix has a misleading name in that it doesn't actually conduct electricity, so I then buffed the railtops using a coffee stirrer which removed the electrofix and some of the blackening to give a used look to the rails. The final step was to paint the sleepers which I did using RailMatch sleeper grime.

Amazingly after all that the rails still conduct power nicely and the locomotive still moves, and I think the whole thing looks much more convincing than the ready-to-run track I was using before.

Tuesday, November 18, 2014

Go Your Own (Permanent) Way

As Paul was kind enough to turn me a set of brass track gauges I no longer have any excuse for not trying to hand build some OO9 gauge track. Paul has already used his gauges to build a working point, but I decided to start with something a little simpler; a 30cm straight piece of track.

As Paul was kind enough to turn me a set of brass track gauges I no longer have any excuse for not trying to hand build some OO9 gauge track. Paul has already used his gauges to build a working point, but I decided to start with something a little simpler; a 30cm straight piece of track.Of course, deciding to have a go at making my own track was the easy part, working out which parts I was going to use was a bit harder. The easy part was the sleepers. I'm using 3mm wide strips of copper clad PCB cut to a length of approximately 19.25mm (based on a couple of measurements from some PECO stuff I had kicking around). The rail was a lot harder though. The OO9 gauge track I've bought previously uses code 80 rail. The rails are measured in 1/1000's of an inch, so code 80 is 0.080" high. For a light railway this looks a little on the large side and many people use a lighter rail. For example, Paul used code 55 steel rail to build his point, which is 0.055" high. The problem I had was that I wanted to avoid using steel rail as previous experience shows that it does corrode over time, much more so than modern nickel silver rail. In the end I've compromised and used code 60 nickel silver rail from PECO. This rail (PECO IL-1) is a little odd in that it is designed to be used for either Z gauge (which is really tiny) or as conductor rail in 4mm, but it seems perfect for OO9. C&L Finescale stock both the sleepers and the rail and so an order was placed.

Once the parts turned up the first job was to cut the sleepers. The copper clad PCB turns up in strips the right width (3mm) but 17" in length. Fortunately a razor saw cuts through the PCB easily, the problem is how to cut consistent lengths. I could have just measured the strip and marked it up, but I decided I'd make up a little jig to aid the process. This jig sits nicely in my small mitre box and when pushed up against the blade of the razor saw ensures a consistent sleeper length. Once I'd cut a couple of strips into separate sleepers, I then turned to building the track.

I started by drawing up a template on the computer to aid in positioning the sleepers and rails. This was easy for a straight section, but if want to build more complex track in the future will need a little more thought. The sleepers were then stuck to the template using double sided tape, and then the first rail was soldered in place, using coffee stirrers to hold it down while I applied the soldering iron. Once the first rail was soldered to every sleeper I could move on to the tricky bit of adding the second rail.

It turned out that with the track gauges Paul had made me, and some more coffee stirrers, fitting the second rail was nice and straightforward and before long I had something that actually looked like a piece of track. Even better a quick test with a wagon and it looked like it might actually work too. What I'd forgotten to do though was to file a gap into each sleeper to ensure that the rails weren't electrically joined. Fortunately on the straight track it was fairly easy to get a file in between the rails to remove some of the copper; in the future I'll definitely be doing this before I solder the rails down. Finally I removed the track from the template, soldered a wire to each rail and then had a go with letting an actual locomotive run along the track.

I opted to try it out with the small diesel I built from the Narrow Planet kit, as the motor would be a lot easier to replace if everything went wrong than it would on the Quary Hunslet, but fortunately, as you can see, it all worked perfectly. In it's current form the track isn't going to win any beauty contests but it should clean up nicely and now I know that I can at least build plain track which is useable so I'll call that success.

Monday, November 17, 2014

Jiggery-Pokery

Given how much "fun" people had guessing the use for a pile of plastic tagliatelle I thought I'd show you the small jig I've just put together to help with another modelling task. So does anyone know what I'm using this for?

Saturday, November 15, 2014

Canopus: Three Out of Four Ain't Bad

Just a short update on Canopus today. If you remember the last time we saw Canopus I'd fixed the retaining nuts for the coupling rods on using threadlocker and everything still seemed to work. Well today I've gone one step further and trimmed the crank pins and filed down the retaining nuts. Amazingly it all still works.

Just a short update on Canopus today. If you remember the last time we saw Canopus I'd fixed the retaining nuts for the coupling rods on using threadlocker and everything still seemed to work. Well today I've gone one step further and trimmed the crank pins and filed down the retaining nuts. Amazingly it all still works.I did have one small problem in that one of the four retaining nuts came loose once I'd filed it down. I'm guessing I'd not got the threadlocker all the way along the thread. Worse when trying to reattach it, the now very thin nut, went pinging off across my study, destination unknown. With some difficulty I managed to get a new nut on to the tiny remaining crank pin along with lots of threadlocker. I then filed this nut down. Unfortunately once filed down it was also loose, so this one has been soldered in place.

Wednesday, November 12, 2014

A Tiny Brick Shed

Okay, so I'm easily seduced by shiny brass models.

This one went together just as easily as the wooden shed. I haven't started painting either of them yet as I haven't been at home when it hasn't been raining so I've been unable to spray them with primer. Hopefully the weather will improve and I can finish these off soon. I did, however, pick up a pot of RailMath Dark Brick (#2424) on the way home so I think I now have the paints I need to paint both models.

This one went together just as easily as the wooden shed. I haven't started painting either of them yet as I haven't been at home when it hasn't been raining so I've been unable to spray them with primer. Hopefully the weather will improve and I can finish these off soon. I did, however, pick up a pot of RailMath Dark Brick (#2424) on the way home so I think I now have the paints I need to paint both models.

Tuesday, November 11, 2014

A Tiny Wooden Shed

So here we have the first of the two sheds from the Severn Models kit I showed you yesterday. As expected it went together nice and easily. I soldered everything but the barge boards (just too fiddly) even though the instructions say to just use glue. In retrospect I think this was a good idea as I had problems with the barge boards as the superglue took an awful long time to grab properly. As you can see it really is tiny, given that it's sat on a 50p piece.

So that's half the kit built (there is the brick shed to go) and I think we can agree it builds up into a nice model. I'll paint this one next before building the other shed, as I know how to paint old looking wood, but I've no idea how to go about painting brick work.

So that's half the kit built (there is the brick shed to go) and I think we can agree it builds up into a nice model. I'll paint this one next before building the other shed, as I know how to paint old looking wood, but I've no idea how to go about painting brick work.

Monday, November 10, 2014

A House in Your Hand

A shiny new brass kit fell through the letterbox today. Given that I've shifted to modelling at 4mm to the foot scale from the 2mm scale of N gauge and have now boxed up and stored Jerusalem in the loft (to make way for me as yet unannounced new OO9 gauge layout) you may be surprised to see that it is in fact an N gauge kit.

I didn't actually buy this kit in the normal sense of the verb "to buy". This is actually a reward for backing a crowd funding project on Kickstarter. Specifically the project aimed at developing a number of etched brass building kits for N gauge model railways with the tag line being "A House in Your Hand". Now while there was the option of lots of lovely kits for large buildings, given that I wasn't modelling in N gauge at the moment, I went for the cheaper option of a kit for two small sheds, as a way of getting something to play with while showing my support for the project.

Now you do have to be careful with Kickstarter projects, in that you are essentially putting up money to fund the development of something that might not turn out to be feasible. There have been some projects that have raised huge amounts of money yet failed to deliver on their promises, so it really is buyer beware. My rule of thumb is never back a project for more money than you would be willing to write off. So far I've backed 10 projects and four have delivered. Five of them have completion dates in the future but one, in fact the first project I backed, should have finished in January, so is at least 8 months behind schedule. This was also an N gauge related project, but I'm now sceptical that it will ever grace this blog. Anyway back to this kit...

First impressions are that the etching looks great, although the instructions are a little thin. There is a side of A4 telling you general things about building brass kits (they suggest superglue but I think I'll solder for added strength), and then two exploded diagrams one for each shed. Unfortunately in a couple of places the orientation of some parts (barge boards mostly) is a little unclear, although I think once I actually try to assemble it things will become more obvious.

Currently the kits aren't publicly available to buy, but a website for Severn Models is under construction so hopefully that will change shortly. While I have no immediate use for these sheds I'll be assembling and painting them when I get a chance so I'll let you know how I get on.

I didn't actually buy this kit in the normal sense of the verb "to buy". This is actually a reward for backing a crowd funding project on Kickstarter. Specifically the project aimed at developing a number of etched brass building kits for N gauge model railways with the tag line being "A House in Your Hand". Now while there was the option of lots of lovely kits for large buildings, given that I wasn't modelling in N gauge at the moment, I went for the cheaper option of a kit for two small sheds, as a way of getting something to play with while showing my support for the project.

Now you do have to be careful with Kickstarter projects, in that you are essentially putting up money to fund the development of something that might not turn out to be feasible. There have been some projects that have raised huge amounts of money yet failed to deliver on their promises, so it really is buyer beware. My rule of thumb is never back a project for more money than you would be willing to write off. So far I've backed 10 projects and four have delivered. Five of them have completion dates in the future but one, in fact the first project I backed, should have finished in January, so is at least 8 months behind schedule. This was also an N gauge related project, but I'm now sceptical that it will ever grace this blog. Anyway back to this kit...

First impressions are that the etching looks great, although the instructions are a little thin. There is a side of A4 telling you general things about building brass kits (they suggest superglue but I think I'll solder for added strength), and then two exploded diagrams one for each shed. Unfortunately in a couple of places the orientation of some parts (barge boards mostly) is a little unclear, although I think once I actually try to assemble it things will become more obvious.

Currently the kits aren't publicly available to buy, but a website for Severn Models is under construction so hopefully that will change shortly. While I have no immediate use for these sheds I'll be assembling and painting them when I get a chance so I'll let you know how I get on.

Sunday, November 9, 2014

Canopus: Biting The Bullet

So I've finally bitten the bullet and permanently attached the coupling rods on Canopus. The good news is that everything still seems to turn freely under power so it doesn't look like I've messed anything up..... phew!

The instructions say to use solder to affix the retaining nuts in place. Experience from building the Quarry Hunslet suggests this doesn't work very well. The problem is that you need to fix the nut before snipping off the excess pin and filling the nut thickness down. When soldering the nuts the solder doesn't penetrate all the way through the nut which means when you start filling it down the first thing you do is file off the solder and the nut becomes loose. On the Quarry Hunslet I secured the coupling rod in place with superglue but still found this difficult as you get so little time to check and adjust things.

For Canopus I took a slightly different approach and have used LOCTITE 243 medium strength threadlocker. This gives me (according to the datasheet) 5 minutes fixture time (that's for brass, it's 10 minutes for stainless steel). Also unlike superglue it is designed to be reversible, assuming you can supply 26 Newton-metres of torque. I used a slip of paper to try and stop the stuff getting anywhere it shouldn't as well as ensuring that I didn't over-tighten the nuts. This seems to have worked well although removing the last bits of paper was a bit of a pain.

I haven't yet removed the excess crank pin or filled down the nut (this was as much stress as I wanted today) but having had it on the rolling rod everything seems to be working nicely. You can tell that the threadlocker is working as previously running in one direction would cause the nuts to work loose which is no longer happening. Now I've got past this point hopefully progress will pick up a little.

The instructions say to use solder to affix the retaining nuts in place. Experience from building the Quarry Hunslet suggests this doesn't work very well. The problem is that you need to fix the nut before snipping off the excess pin and filling the nut thickness down. When soldering the nuts the solder doesn't penetrate all the way through the nut which means when you start filling it down the first thing you do is file off the solder and the nut becomes loose. On the Quarry Hunslet I secured the coupling rod in place with superglue but still found this difficult as you get so little time to check and adjust things.

For Canopus I took a slightly different approach and have used LOCTITE 243 medium strength threadlocker. This gives me (according to the datasheet) 5 minutes fixture time (that's for brass, it's 10 minutes for stainless steel). Also unlike superglue it is designed to be reversible, assuming you can supply 26 Newton-metres of torque. I used a slip of paper to try and stop the stuff getting anywhere it shouldn't as well as ensuring that I didn't over-tighten the nuts. This seems to have worked well although removing the last bits of paper was a bit of a pain.

I haven't yet removed the excess crank pin or filled down the nut (this was as much stress as I wanted today) but having had it on the rolling rod everything seems to be working nicely. You can tell that the threadlocker is working as previously running in one direction would cause the nuts to work loose which is no longer happening. Now I've got past this point hopefully progress will pick up a little.

Dry Stone Walling

Some of you may remember that back in March I built a couple of short sections of stone walling using brick papers from scalescenes.com. The first attempt was wrong as the stones were too big, and while the second attempt was better, the wall was just too flat with no relief. Having now abandoned brick papers for full structures in favour of embossed plastikard I decided I needed to have another go at building a stone wall. The result is this little test piece (using the driver from the Brian Madge Quarry Hunslet kit to give a sense of scale).

Personally I think this looks an order of magnitude better than my previous attempts. It did, however, taken an order of magnitude longer to produce as well. In fact that short piece of wall took all day, although some of that was waiting for DAS clay to dry. What you are looking at is a wall where each stone was cut and laid separately to produce a dry stone wall; albeit with PVA to keep the stones in place.

The technique I've used is based on Ian Nuttall's description of how he built dry stone walls for his layout (February 2013 edition of Railway Modeller). The idea is to create 6mm wide strips of DAS clay of varying heights that can be cut to make individual stones and used to model a 1' 6" wide wall. Rolling, measuring and and cutting DAS clay to the right sizes would be a pain, which is where the plastic tagliatelle comes in to play.

I built a jig from a sheet of 2mm plastikard and various sized square sections of plastruct. I used 1.5mm, 2mm, 2.5mm, 3.2mm, and 4mm sections to give five channels 6mm wide allowing me to model stones 4 1/2", 6", 7 1/2", 9 2/3" and 1' tall by simply pushing DAS into the channels of the jig. The problem is removing the DAS from the jig. The trick here is to place one of the plastic strips at the bottom of the channel, then add the DAS, and then just lift the plastic strip to remove the clay. Once the DAS has dried the plastic strip peels off easily and can be reused.

Once the clay strips have dried (I should possibly have left them a little longer but I was getting inpatient) they can be cut into individual stones; I found my track cutters worked really well for this bit. The wall is started by laying down a thin ribbon of PVA and placing the first course of stones. Small dabs of PVA are then used to add the further layers trying to avoid any leaking out the side of a join. I aimed for a level topped four foot high wall, before then adding the capping stones, which were slightly rounded, to give a wall approximately 4' 6" high. This seems to look about right next to the figure.

I painted the wall initially with RailMatch weathered stone (#2426) before giving the whole thing a black wash making sure to get the wash deep into the cracks where the base coat hadn't necessarily flowed. I then lightly dry brushed more weathered stone and some khaki (Model Color #988) to add a little variation. The final touch (which is mostly hidden behind the greenery) was to dry brush a little brown sand (Model Color #876) along the bottom of the wall to represent dirt having splashed up.

While the wall looked good at that point (I forgot to take any photos) I thought it was worth adding more scenery to see how it would look in the context of a layout rather than in isolation. I used some cheap burnt umber acrylic (I bought a large tube ages ago from WH Smiths) to provide a base colour and to hide the white cardboard. I then used Woodland Scenics green blend blended turf to provide ground cover before adding various shades of Woodland Scenics bushes and foliage clumps for bushes around the wall edges. The final touch was a little bit of yellow flowering foliage to the right side to add more colour.

Hopefully you will all agree that this looks a lot better than my previous brick paper attempts at making walls. Having said that it still isn't perfect, mostly as I think the proportion of large stones in the wall is too high; locally the walls are mostly small stones rather than large chunks. Changing the proportion of stone sizes though is easy so I think this is another scenic technique that I'm now happy with so another piece of the puzzle falls into place.

Personally I think this looks an order of magnitude better than my previous attempts. It did, however, taken an order of magnitude longer to produce as well. In fact that short piece of wall took all day, although some of that was waiting for DAS clay to dry. What you are looking at is a wall where each stone was cut and laid separately to produce a dry stone wall; albeit with PVA to keep the stones in place.

The technique I've used is based on Ian Nuttall's description of how he built dry stone walls for his layout (February 2013 edition of Railway Modeller). The idea is to create 6mm wide strips of DAS clay of varying heights that can be cut to make individual stones and used to model a 1' 6" wide wall. Rolling, measuring and and cutting DAS clay to the right sizes would be a pain, which is where the plastic tagliatelle comes in to play.

I built a jig from a sheet of 2mm plastikard and various sized square sections of plastruct. I used 1.5mm, 2mm, 2.5mm, 3.2mm, and 4mm sections to give five channels 6mm wide allowing me to model stones 4 1/2", 6", 7 1/2", 9 2/3" and 1' tall by simply pushing DAS into the channels of the jig. The problem is removing the DAS from the jig. The trick here is to place one of the plastic strips at the bottom of the channel, then add the DAS, and then just lift the plastic strip to remove the clay. Once the DAS has dried the plastic strip peels off easily and can be reused.

Once the clay strips have dried (I should possibly have left them a little longer but I was getting inpatient) they can be cut into individual stones; I found my track cutters worked really well for this bit. The wall is started by laying down a thin ribbon of PVA and placing the first course of stones. Small dabs of PVA are then used to add the further layers trying to avoid any leaking out the side of a join. I aimed for a level topped four foot high wall, before then adding the capping stones, which were slightly rounded, to give a wall approximately 4' 6" high. This seems to look about right next to the figure.

I painted the wall initially with RailMatch weathered stone (#2426) before giving the whole thing a black wash making sure to get the wash deep into the cracks where the base coat hadn't necessarily flowed. I then lightly dry brushed more weathered stone and some khaki (Model Color #988) to add a little variation. The final touch (which is mostly hidden behind the greenery) was to dry brush a little brown sand (Model Color #876) along the bottom of the wall to represent dirt having splashed up.

While the wall looked good at that point (I forgot to take any photos) I thought it was worth adding more scenery to see how it would look in the context of a layout rather than in isolation. I used some cheap burnt umber acrylic (I bought a large tube ages ago from WH Smiths) to provide a base colour and to hide the white cardboard. I then used Woodland Scenics green blend blended turf to provide ground cover before adding various shades of Woodland Scenics bushes and foliage clumps for bushes around the wall edges. The final touch was a little bit of yellow flowering foliage to the right side to add more colour.

Hopefully you will all agree that this looks a lot better than my previous brick paper attempts at making walls. Having said that it still isn't perfect, mostly as I think the proportion of large stones in the wall is too high; locally the walls are mostly small stones rather than large chunks. Changing the proportion of stone sizes though is easy so I think this is another scenic technique that I'm now happy with so another piece of the puzzle falls into place.

Saturday, November 8, 2014

Plastic Tagliatelle

Just a little teaser for today's post. I spent a bit of time yesterday cutting a plastic food bag into strips 6mm wide by about 29cm long (the width of the bag). These will be used to help with a specific bit of scenic modelling. Anyone fancy a guess at what?

Friday, November 7, 2014

Track Gauges

Today saw the arrival in the post of these two excellent OO9 track gauges. Some of you will have already seen these, as they were turned for me by Paul and he has already blogged about how he made them.

I'd recently started a discussion over on the Narrow Gauge Railway Modelling forum about forming tight curves (unfortunately you need to be a member to read this), and a number of people suggested that instead of trying to tightly bend flexitrack I should instead build my own track. The problem was that I had no idea what height of rail I wanted to use and all the commercial track gauges are designed for specific rail types. Paul suggested that he could easily turn a set of gauges that could be used with any height of rail, and so we now both have a set of OO9 track gauges, and will both be having a go at building some track (the photo shows them sat on some standard PECO crazy track).

I'm going to start with some plain track, although Paul says he might start with a point. Given the fun I've had getting good running through shop bought points, I'll definitely not be building my own just yet, but plain track seems doable.

While the track will be OO9 it won't be for the mythical 77 Box Lane layout, as I'm still not entirely happy with the track plan. I do, however, have a new track plan in mind that will allow me scope to practice track laying and more scratch-building of structures. That plan though will wait for another post.

Thanks again Paul, hopefully the track will look half as good as the track gauges!

I'd recently started a discussion over on the Narrow Gauge Railway Modelling forum about forming tight curves (unfortunately you need to be a member to read this), and a number of people suggested that instead of trying to tightly bend flexitrack I should instead build my own track. The problem was that I had no idea what height of rail I wanted to use and all the commercial track gauges are designed for specific rail types. Paul suggested that he could easily turn a set of gauges that could be used with any height of rail, and so we now both have a set of OO9 track gauges, and will both be having a go at building some track (the photo shows them sat on some standard PECO crazy track).

I'm going to start with some plain track, although Paul says he might start with a point. Given the fun I've had getting good running through shop bought points, I'll definitely not be building my own just yet, but plain track seems doable.

While the track will be OO9 it won't be for the mythical 77 Box Lane layout, as I'm still not entirely happy with the track plan. I do, however, have a new track plan in mind that will allow me scope to practice track laying and more scratch-building of structures. That plan though will wait for another post.

Thanks again Paul, hopefully the track will look half as good as the track gauges!

Wednesday, November 5, 2014

Hay Wagon

The mathematically inclined amongst you may have spotted that in yesterday's post I mentioned that I'd printed eight underframes but only four bodies of the Sand Hutton wagons. This wasn't because I wanted a surplus of underframes but because I'd also printed a second set of parts. While there are no drawings provided, and only two blurry photos, the book describes a wood frame 16 ft long and 6 ft wide that was fitted to two underframes and used to carry 70 trusses of hay.

Obviously with so little detail to go on I'm not sure how accurate this model is, but it clips nicely to two of the underframes and once I've figured out how to model 70 trusses of hay will be well hidden anyway.

Obviously with so little detail to go on I'm not sure how accurate this model is, but it clips nicely to two of the underframes and once I've figured out how to model 70 trusses of hay will be well hidden anyway.

Tuesday, November 4, 2014

A Partial Success

Today saw the delivery of my most recent 3D print order from Shapeways which contained the Sand Hutton wagons you've recently seen me design. Unfortunately the models were not quite as much of a success as I would have liked, although I don't think the problem is with the 3D model, but we'll get to that later. Let's start by showing you the wagon in it's two basic forms; sorry that the photos aren't very clear but the translucent nature of the prints makes them a nightmare to photograph.

One of the main features of these wagons was that the body could be lifted clear of the underframe (hence the four lifting eyes) and so I modelled the two parts separately. As you can see they fit together quite nicely and they look the part. So far so good. The problem is that what you are seeing here is a bit of a cheat.

Firstly, I should admit that I tried to be clever with this model and that has at least contributed to the problems. In reality both sides of the wagon were hinged to allow easy access to the contents, and I decided to try and model that. My plan was to use 0.2mm nickel silver rod not only to add some of the fine details but also to act as a hinge allowing the side doors to open. In the photo above I've actually glued the sides in place so that I can check the look of the model, as I can't get the nickel silver rod through the holes in the parts. I think this is actually just because I can't clean them out properly and while I thought I had a 0.2mm drill I don't (my smallest is 0.3mm) so until the ones I've ordered arrive I have resorted to glue; something I was going to try anyway as not everyone will want the hassle of fitting the hinges.

Now I grouped the wagons into a number of models when I placed the order, and in total ordered four wagon bodies and eight underframes. Unfortunately when the prints arrived three of the bodies were broken and four of the underframes were also broken. In this photo you can see a complete body and underframe on the left, and then a broken body, and a broken underframe.

Initially I thought the wagon bodies might have broken simply because the sprue I'd used wasn't thick enough. looking closely though it is clear that there is no break and I think what has happened is that Shapeways have deliberately cut the model into two parts for some reason. Given that they placed the break on a sprue it is annoying (I paid for the sprue material which I didn't need to add if they are going to break it) but doesn't render the part unusable (although the support material has ended up in a different orientation than I expected which has obscured some details). The underframes though are a different matter.

The underframes have again been broken into two, and this must have happened prior to printing as the axle boxes, which are joined by the sprue containing the coupling hooks) have been cleanly separated from the rest of the frame. This can't have been accidental. Unfortunately this means I'd have to glue the axle boxes in place and I doubt the model would be very strong as a result. It's unclear why this has happened, especially as some of the parts printed perfectly, but I'm assuming it was human intervention in some way. I've got a complaint in to Shapeways about this as they shouldn't be breaking models at arbitrary points as clearly they won't know what is functional and what is sprue material etc. Hopefully I'll get a sensible answer, but I'll be asking for a refund rather than a reprint while I check the hinges and finalize other details. What this means of course is that these models won't be available for a while as I can't run the risk of them being misprinted for anyone else.

I'll get this model painted up at some point, and when the 0.2mm drills arrive I'll see how the hinges work (if at all), before tweaking the 3D model and trying for a second prototype print.

One of the main features of these wagons was that the body could be lifted clear of the underframe (hence the four lifting eyes) and so I modelled the two parts separately. As you can see they fit together quite nicely and they look the part. So far so good. The problem is that what you are seeing here is a bit of a cheat.

Firstly, I should admit that I tried to be clever with this model and that has at least contributed to the problems. In reality both sides of the wagon were hinged to allow easy access to the contents, and I decided to try and model that. My plan was to use 0.2mm nickel silver rod not only to add some of the fine details but also to act as a hinge allowing the side doors to open. In the photo above I've actually glued the sides in place so that I can check the look of the model, as I can't get the nickel silver rod through the holes in the parts. I think this is actually just because I can't clean them out properly and while I thought I had a 0.2mm drill I don't (my smallest is 0.3mm) so until the ones I've ordered arrive I have resorted to glue; something I was going to try anyway as not everyone will want the hassle of fitting the hinges.

Now I grouped the wagons into a number of models when I placed the order, and in total ordered four wagon bodies and eight underframes. Unfortunately when the prints arrived three of the bodies were broken and four of the underframes were also broken. In this photo you can see a complete body and underframe on the left, and then a broken body, and a broken underframe.

Initially I thought the wagon bodies might have broken simply because the sprue I'd used wasn't thick enough. looking closely though it is clear that there is no break and I think what has happened is that Shapeways have deliberately cut the model into two parts for some reason. Given that they placed the break on a sprue it is annoying (I paid for the sprue material which I didn't need to add if they are going to break it) but doesn't render the part unusable (although the support material has ended up in a different orientation than I expected which has obscured some details). The underframes though are a different matter.

The underframes have again been broken into two, and this must have happened prior to printing as the axle boxes, which are joined by the sprue containing the coupling hooks) have been cleanly separated from the rest of the frame. This can't have been accidental. Unfortunately this means I'd have to glue the axle boxes in place and I doubt the model would be very strong as a result. It's unclear why this has happened, especially as some of the parts printed perfectly, but I'm assuming it was human intervention in some way. I've got a complaint in to Shapeways about this as they shouldn't be breaking models at arbitrary points as clearly they won't know what is functional and what is sprue material etc. Hopefully I'll get a sensible answer, but I'll be asking for a refund rather than a reprint while I check the hinges and finalize other details. What this means of course is that these models won't be available for a while as I can't run the risk of them being misprinted for anyone else.

I'll get this model painted up at some point, and when the 0.2mm drills arrive I'll see how the hinges work (if at all), before tweaking the 3D model and trying for a second prototype print.

Subscribe to:

Posts (Atom)