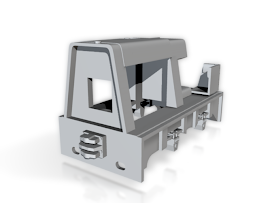

After all the positive comments on the Hunslet axlebox I've pushed on with the rest of the model I've been working on. Given that I'm now planning a layout based around the test track at the Robert Hudson Ltd factory I decided I needed an appropriate locomotive. Hudson's didn't manufacture locomotives themselves but instead entered into partnerships with other firms to sell branded locomotives. One of these partnerships was with the Hunslet Engine Company and I decided to have a go at modelling one of their tiny 24HP diesel locomotives. These were produced for a number of different narrow gauges and in a variety of cab configurations. My current model is based around a cabless 2' 6" gauge version.

If you are at all familiar with the prototype then you'll notice that quite a few bits of body work are missing. The plan is to add these using etched brass parts which I have yet to draw up. In fact I'm hoping to use the model with different etched parts to produce different versions with different cabs.

This is by far the most complex model I've ever attempted to build. Not only is the 3D printed part quite complex, there will be the etched parts, and I'm intending to build the chassis as well as I was unable to find one with the right wheel base; you may remember I've already bought some parts for this. I've no idea if this will work or not as there are so many parts I'll need to get just right, but if I do manage to pull it off then, depending how complex it is to assemble, it might become a Narrow Planet kit, assuming there is enough interest.

Tuesday, December 30, 2014

Monday, December 29, 2014

Christmas Modelling

I hope you've all had a great Christmas and are looking forward to 2015. I'd planned on doing some more 3D modelling over the holiday (I wasn't spending it at home and my modelling stuff has all been packed away for the holidays), but this is the sum total of the modelling I achieved; a Hunslet axlebox.

Of course a lack of modelling just means I had a great Christmas with lots to do and friends to see. Unfortunately I'm back at work this week, so I'm not likely to get much more modelling done, but when I do at least I'll have an axlebox around which to build a model!

Of course a lack of modelling just means I had a great Christmas with lots to do and friends to see. Unfortunately I'm back at work this week, so I'm not likely to get much more modelling done, but when I do at least I'll have an axlebox around which to build a model!

Friday, December 19, 2014

Chimney Pots and Finials

The Lynton and Barnstaple Railway has a long history, and efforts are now underway to rebuild substantial portions of the line. In parallel to this real world expansion a number of model railway companies have started to produce models related to the railway, specifically the station at Woody Bay. For example, here is a photo of the station as well as a photo of the model produced by Bachmann.

Now while the model is exceptionally detailed there are a couple of things that are missing or not quite right. Most obviously the chimney pots are wrong. The real chimneys are quite ornate and very distinctive, yet the model has very plain chimney pots. Also the roof sports ornate finials which are entirely missing from the model. I'm guessing both these changes were made as the details would be too fine to mass produce and would have had to be hand fitted increasing the cost of the models.

Given that I'm not modelling the Lynton and Barnstaple railway I hadn't actually noticed the problem as I'd not looked closely at the models. The members of the Lynton and Barnstaple Modelling Yahoo! Group had noticed though and they asked Narrow Planet if they would be willing to produce 3D printed chimney pots and finials to complement the building models. At this point you may be asking how I know this? The answer is that I'm the newest Narrow Planet designer, and the chimney pots and finials are the first products I've designed to be released.

Working from scale drawings and plenty of photos I was able to produce a 3D model of both the chimney pots and the finials, and I've now received the first test prints. I find photographing raw FUD prints difficult as all the detail tends to disappear so I painted one chimney to help show the detail (RailMatch freight Bauxite followed by a thin black wash).

Personally I think these have turned out really nicely and as there was no problem with the test prints they are now available to buy. They aren't listed yet on the Narrow Planet website, but you can order them via e-mail. A sprue of 10 chimneys will set you back £6, while a sprue of 10 finials will cost you £3; both those prices include UK P&P. Hopefully the odd chimney pots will appeal to a wide range of modellers who might be looking for something a little different as well as those modelling the Lynton and Barnstaple Railway.

For those wondering what this means for Penistone Railway Works my answer is that for now you won't see any difference. All the models that are currently available will remain so, and there may be new models in the future that don't fit well with Narrow Planet. What it does mean though is that I can now contemplate models which would only be possible using multiple materials rather than just single printed items sold via Shapeways. Hopefully this will mean more models for everyone to enjoy.

Now while the model is exceptionally detailed there are a couple of things that are missing or not quite right. Most obviously the chimney pots are wrong. The real chimneys are quite ornate and very distinctive, yet the model has very plain chimney pots. Also the roof sports ornate finials which are entirely missing from the model. I'm guessing both these changes were made as the details would be too fine to mass produce and would have had to be hand fitted increasing the cost of the models.

Given that I'm not modelling the Lynton and Barnstaple railway I hadn't actually noticed the problem as I'd not looked closely at the models. The members of the Lynton and Barnstaple Modelling Yahoo! Group had noticed though and they asked Narrow Planet if they would be willing to produce 3D printed chimney pots and finials to complement the building models. At this point you may be asking how I know this? The answer is that I'm the newest Narrow Planet designer, and the chimney pots and finials are the first products I've designed to be released.

Working from scale drawings and plenty of photos I was able to produce a 3D model of both the chimney pots and the finials, and I've now received the first test prints. I find photographing raw FUD prints difficult as all the detail tends to disappear so I painted one chimney to help show the detail (RailMatch freight Bauxite followed by a thin black wash).

Personally I think these have turned out really nicely and as there was no problem with the test prints they are now available to buy. They aren't listed yet on the Narrow Planet website, but you can order them via e-mail. A sprue of 10 chimneys will set you back £6, while a sprue of 10 finials will cost you £3; both those prices include UK P&P. Hopefully the odd chimney pots will appeal to a wide range of modellers who might be looking for something a little different as well as those modelling the Lynton and Barnstaple Railway.

For those wondering what this means for Penistone Railway Works my answer is that for now you won't see any difference. All the models that are currently available will remain so, and there may be new models in the future that don't fit well with Narrow Planet. What it does mean though is that I can now contemplate models which would only be possible using multiple materials rather than just single printed items sold via Shapeways. Hopefully this will mean more models for everyone to enjoy.

Wednesday, December 10, 2014

Pac-Man

While I'd never normally advocate adding graffiti to anything, this addition to the damaged paintwork on the Northern Rail train I took to work on Monday really did make me smile.

Saturday, December 6, 2014

Hudson's Pizza

So the time has finally come to unveil the plan for my next layout. Given that I'm still not happy with the track plan for 77 Box Lane that will stay on the drawing board for now, and this is an entirely new and different layout.

One of the things I liked about my N gauge layout, Jerusalem (which is now boxed up and being stored in the loft) was that it had a roundy-roundy track plan so I could just watch the trains go by. It was also useful for running in and testing new locomotives as they could be left going for hours if necessary without any intervention. Given the size I had to play with 77 Box Lane was always going to be an end-to-end layout and while I'm happy with that (although not the current track plan) I did feel it would be useful to have some form of continuous run test track, even if that was a simple circle of temporary track.

I wasn't actively planning a new layout when a random comment sent me off on a bit of historical research. I grew up in Morley, a small town just outside Leeds, and I've known for a long time (pretty much as long as I can remember) that many of the early builders of locomotives and rolling stock were based in and around Leeds; it's one of the reasons I have a soft spot for the Quarry Hunslet locomotives. What I didn't know, until recently, was that I actually grew up less than three miles from the main works of one of the companies.

Robert Hudson Ltd was founded in 1865 and had it's main works at Gildersome a small village just outside Morley (it's officially been part of Morley since 1937). This was a huge site covering 38 acres and was well served by a 2 foot tramway. Raw materials and finished products arrived and left the site via the standard gauge branch line that formed the northern edge of the site. You can see these and many other details on both the 1938 map and a 1928 aerial photograph.

What immediately caught my eye though was the circular feature which is very clear on the map, but unfortunately is unlabelled as to purpose. Zooming in on the photo though and it's purpose becomes clearer. It's a circular test track on which you can see what looks like a couple of wagons.

To me this looks perfect for turning into a pizza layout. It will give me somewhere to test and run in locomotives and wagons while being based on an actual location. There also appears to be a variety of building styles to perfect and some dry stone walling. I know that so far I've not built any Hudson wagons or locomotives which they re-sold (they didn't build their own but rather re-sold those produced by companies such as Hudswell Clarke, Kerr Stuart, and Hunslet) but I can always apply Rule 1 of railway modelling; it's my trainset so I'll run whatever I want to!

The problem I have is that this grainy photo contains the only details I have on the buildings surrounding the test track. There is a drawing in Alan J. Haigh's book on the foundry (published by the Moseley Railway Trust) but it doesn't provide any extra details. So does anyone know of any further drawings or photos of that area of the works that might show more details of the buildings. If you do please leave a comment.

From some rough measurements, I believe that I can fit the circle of track and the buildings immediately surrounding it onto a board that will fit into the box I originally bought for Jerusalem but which was about 1cm too small. So this means it will fit on my desk and I'll have storage for it. The next step will be a full scale mockup (starting from the map) to check everything will fit and then I can make a start on the baseboard and then building some track. This should be fun!

One of the things I liked about my N gauge layout, Jerusalem (which is now boxed up and being stored in the loft) was that it had a roundy-roundy track plan so I could just watch the trains go by. It was also useful for running in and testing new locomotives as they could be left going for hours if necessary without any intervention. Given the size I had to play with 77 Box Lane was always going to be an end-to-end layout and while I'm happy with that (although not the current track plan) I did feel it would be useful to have some form of continuous run test track, even if that was a simple circle of temporary track.

I wasn't actively planning a new layout when a random comment sent me off on a bit of historical research. I grew up in Morley, a small town just outside Leeds, and I've known for a long time (pretty much as long as I can remember) that many of the early builders of locomotives and rolling stock were based in and around Leeds; it's one of the reasons I have a soft spot for the Quarry Hunslet locomotives. What I didn't know, until recently, was that I actually grew up less than three miles from the main works of one of the companies.

Robert Hudson Ltd was founded in 1865 and had it's main works at Gildersome a small village just outside Morley (it's officially been part of Morley since 1937). This was a huge site covering 38 acres and was well served by a 2 foot tramway. Raw materials and finished products arrived and left the site via the standard gauge branch line that formed the northern edge of the site. You can see these and many other details on both the 1938 map and a 1928 aerial photograph.

What immediately caught my eye though was the circular feature which is very clear on the map, but unfortunately is unlabelled as to purpose. Zooming in on the photo though and it's purpose becomes clearer. It's a circular test track on which you can see what looks like a couple of wagons.

To me this looks perfect for turning into a pizza layout. It will give me somewhere to test and run in locomotives and wagons while being based on an actual location. There also appears to be a variety of building styles to perfect and some dry stone walling. I know that so far I've not built any Hudson wagons or locomotives which they re-sold (they didn't build their own but rather re-sold those produced by companies such as Hudswell Clarke, Kerr Stuart, and Hunslet) but I can always apply Rule 1 of railway modelling; it's my trainset so I'll run whatever I want to!

The problem I have is that this grainy photo contains the only details I have on the buildings surrounding the test track. There is a drawing in Alan J. Haigh's book on the foundry (published by the Moseley Railway Trust) but it doesn't provide any extra details. So does anyone know of any further drawings or photos of that area of the works that might show more details of the buildings. If you do please leave a comment.

From some rough measurements, I believe that I can fit the circle of track and the buildings immediately surrounding it onto a board that will fit into the box I originally bought for Jerusalem but which was about 1cm too small. So this means it will fit on my desk and I'll have storage for it. The next step will be a full scale mockup (starting from the map) to check everything will fit and then I can make a start on the baseboard and then building some track. This should be fun!

Thursday, December 4, 2014

A Crazy Idea?

I've recently come across drawings for a loco I fancy building. Strangely, for me at least, it's a small 0-4-0 diesel engine rather; the identify of which will, for now at least, remain a mystery. The problem is that with a wheel base of just 2 foot 10 inches I've been unable to find a suitable ready-to-run chassis. Not only did every chassis I could find have a larger wheelbase but I also want the gap between the wheels to be empty and most of them have a solid chassis block. So the crazy idea... I'm going to have a go at building my own chassis for it.

I've no idea if I'll be able to pull off building a chassis from scratch but as you can see I've made a start by buying a bunch of components from Nigel Lawton. This pile includes a motor, pulleys, belts, gears, wheels, and various other items. My plan is to 3D print the basic chassis block and then to add these parts to it. I've got the first prototype chassis on order, although I think it will need a couple of revisions before I get it right, but it should be fun.

I've no idea if I'll be able to pull off building a chassis from scratch but as you can see I've made a start by buying a bunch of components from Nigel Lawton. This pile includes a motor, pulleys, belts, gears, wheels, and various other items. My plan is to 3D print the basic chassis block and then to add these parts to it. I've got the first prototype chassis on order, although I think it will need a couple of revisions before I get it right, but it should be fun.

Monday, December 1, 2014

How to Electrify a Frog

Some of you may remember that since May I've been slowly documenting my attempts at point control (here, here, and here). All the posts so far have dealt with the mechanical side of changing the points and have completely ignored what happens to the power running through the rails.

In theory the PECO points can be used straight from the packet, but from prior experience I won't be doing that ever again. The problem is that, as manufactured, the points rely on the contact between the switch and stock rails to provide power. While this works well with a new point as soon as you try and paint, weather, or ballast the track it is exceedingly likely that the point of contact will be obscured and the power flow will either stop entirely or be very temperamental. On Jerusalem, I had no end of problems with the one scenic point and no amount of careful cleaning would give me a reliable point. The solution to this is to perform a small amount of surgery on the point so that we no longer rely on the contact between the rails to transfer the power.

Before we start altering the point we need to ensure some consistent terminology so that the instructions are clear. So here we have an annotated photo of a right hand PECO crazy track OO9 point.

Now that we are all on the same page here are four simple steps to upgrade the point.

Step 1

Counting from the vee end of the point, use a small razor saw to remove the webbing from under the inner vee rails between the first and second sleepers and also the webbing from under all four rails between sleepers six and seven (helpfully these are the sleepers with writing on the bottom). Be careful not to cut into the rails and try and make sure the sleepers don't slide along the rails.

Step 2

Add a small amount of superglue (the runny kind not a gel) at each point indicated in the photo. Capillary action will help draw the glue into the gap between the rails and sleepers and will help to hold the point together. Once the glue has dried use a small file or fibreglass pen to clean the newly exposed rail surfaces.

Step 3

Solder three wires to the rails as shown. Do not rush this stage as it easy to destroy the point by getting it too hot. My approach was to wrap as much of the point as I could in wet kitchen paper and to allow the rail to cool completely between soldering each joint. The three wires give you access to the track power (red and black) and the vee (white) and can be wired directly into most accessory switches found on point motors. If you don't need access to the track power (i.e. you are feeding the accessory switch from a power bus) then you can remove the left over black and red wires just leaving the bridges between the switch and stock rails.

Step 4

The final step is to electrically isolate the frog and vee from the switch rails. Use a small piercing saw to cut the rails just to the right (when viewed from below) of the sixth sleeper. If you can avoid cutting the webbing then the point will be stronger but I found this impossible with the saw I used. The point can now be connected to the rest of the track not forgetting that you will need to use isolated rail joiners on at least the two vee rails to avoid a short circuit.

When viewed from the top the changes appear minor and the wires can easily be dropped through holes in the baseboard out of sight. The main advantage, as discussed earlier, is that the point can now be painted and ballasted without worrying about retaining a clean contact surface for the switch rails as they are always at the same polarity as the accompanying stock rail.

I'm not going to go into the issue of wiring the point up as this has been covered elsewhere (a quick search for DCC friendly point wiring will set you on the right track) and can be done in a number of different ways depending on the switches etc. you want to use. At some point I'll wire these up to the Cobalt-S lever and have the power switched over at the same time as the servo moving the point, but I know some people will prefer using a micro-switch activated by the moving tie bar etc. Whichever option you choose if you've followed these steps, and not destroyed the point (I killed at least three before I got this worked out) then you should never have an electrical contact issue ever again!

In theory the PECO points can be used straight from the packet, but from prior experience I won't be doing that ever again. The problem is that, as manufactured, the points rely on the contact between the switch and stock rails to provide power. While this works well with a new point as soon as you try and paint, weather, or ballast the track it is exceedingly likely that the point of contact will be obscured and the power flow will either stop entirely or be very temperamental. On Jerusalem, I had no end of problems with the one scenic point and no amount of careful cleaning would give me a reliable point. The solution to this is to perform a small amount of surgery on the point so that we no longer rely on the contact between the rails to transfer the power.

Before we start altering the point we need to ensure some consistent terminology so that the instructions are clear. So here we have an annotated photo of a right hand PECO crazy track OO9 point.

Now that we are all on the same page here are four simple steps to upgrade the point.

Step 1

Counting from the vee end of the point, use a small razor saw to remove the webbing from under the inner vee rails between the first and second sleepers and also the webbing from under all four rails between sleepers six and seven (helpfully these are the sleepers with writing on the bottom). Be careful not to cut into the rails and try and make sure the sleepers don't slide along the rails.

Step 2

Add a small amount of superglue (the runny kind not a gel) at each point indicated in the photo. Capillary action will help draw the glue into the gap between the rails and sleepers and will help to hold the point together. Once the glue has dried use a small file or fibreglass pen to clean the newly exposed rail surfaces.

Step 3

Solder three wires to the rails as shown. Do not rush this stage as it easy to destroy the point by getting it too hot. My approach was to wrap as much of the point as I could in wet kitchen paper and to allow the rail to cool completely between soldering each joint. The three wires give you access to the track power (red and black) and the vee (white) and can be wired directly into most accessory switches found on point motors. If you don't need access to the track power (i.e. you are feeding the accessory switch from a power bus) then you can remove the left over black and red wires just leaving the bridges between the switch and stock rails.

Step 4

The final step is to electrically isolate the frog and vee from the switch rails. Use a small piercing saw to cut the rails just to the right (when viewed from below) of the sixth sleeper. If you can avoid cutting the webbing then the point will be stronger but I found this impossible with the saw I used. The point can now be connected to the rest of the track not forgetting that you will need to use isolated rail joiners on at least the two vee rails to avoid a short circuit.

When viewed from the top the changes appear minor and the wires can easily be dropped through holes in the baseboard out of sight. The main advantage, as discussed earlier, is that the point can now be painted and ballasted without worrying about retaining a clean contact surface for the switch rails as they are always at the same polarity as the accompanying stock rail.

I'm not going to go into the issue of wiring the point up as this has been covered elsewhere (a quick search for DCC friendly point wiring will set you on the right track) and can be done in a number of different ways depending on the switches etc. you want to use. At some point I'll wire these up to the Cobalt-S lever and have the power switched over at the same time as the servo moving the point, but I know some people will prefer using a micro-switch activated by the moving tie bar etc. Whichever option you choose if you've followed these steps, and not destroyed the point (I killed at least three before I got this worked out) then you should never have an electrical contact issue ever again!

Sunday, November 30, 2014

Canopus: Slides Bars

Not long after I started building Canopus I was warned by a fellow modeller that when originally released there was an issue with the slide bars. Essentially in the original kit the slide bars were so close to the coupling rods that there wasn't enough clearance for the crosshead to slide along the bars. Given that a number of changes have been made to the kit since it was released (different, wheels, motors and gears) I was hoping that the problem had been fixed. Unfortunately it seems not.

As you can see in the photo the slide bars are so close to the frames that the filed down retaining nut actually forces them outwards. This means I'm going to have to make some alterations to the part to move the slide bars out a little bit on each side to provide enough clearance. While the slide bars don't fit properly they did highlight that I'd managed to get the cylinder bracket on wonky which I've now fixed, hence the rubbed off paint on the bottom bracket in the photo.

Fortunately I have a copy of an article from the September 2006 issue of 009 News where Phil Savage documented how he went about altering the slide bars. He also hit a problem with them being two short and the crosshead striking the support bracket on the back-stroke. Looking at photos of his completed model though, it looks like he ended up with the cylinders and slide bars being perfectly horizontal while they should be on an angle and I'm wondering if that would change the distance of travel. I'll have to assemble the crossheads before I can see if my model suffers from this second issue as well.

As you can see in the photo the slide bars are so close to the frames that the filed down retaining nut actually forces them outwards. This means I'm going to have to make some alterations to the part to move the slide bars out a little bit on each side to provide enough clearance. While the slide bars don't fit properly they did highlight that I'd managed to get the cylinder bracket on wonky which I've now fixed, hence the rubbed off paint on the bottom bracket in the photo.

Fortunately I have a copy of an article from the September 2006 issue of 009 News where Phil Savage documented how he went about altering the slide bars. He also hit a problem with them being two short and the crosshead striking the support bracket on the back-stroke. Looking at photos of his completed model though, it looks like he ended up with the cylinders and slide bars being perfectly horizontal while they should be on an angle and I'm wondering if that would change the distance of travel. I'll have to assemble the crossheads before I can see if my model suffers from this second issue as well.

Saturday, November 22, 2014

Painted Sheds

Having been side tracked by building some OO9 gauge track, I've finally gone back and painted the two N gauge sheds built from the Severn Models kit. Both models involved me trying a new technique in their painting.

I painted the walls and door of the wooden shed using my standard approach for aged wood which has worked well on the OO9 wagons I've recently been building. This seems to work well for N gauge buildings as well. When it came to the roof, however, I wasn't happy with the very flat look of painted brass. To add a little texture I painted it with RailMatch roof dirt and then blew on a small amount of polyfilla while the paint was still wet. Once the paint had dried I then painted it again to cover the white plaster. This seems to have given a nice surface, although I don't think the same would work in 4mm scale as the texture would still be fairly smooth.

I've never tried painting red brick before and the second shed caused quite a few problems. I tried a number of different approaches before I settled on something that mostly worked. In the end I painted the walls with RailMatch dark brick, and then used thinned down RailMatch weathered stone run into the mortar gaps. A final patchy black wash made things look nice and dirty. The corrugated roof was initially painted with roof dirt before a dry brushing of Model Color London grey. This gave a nice approximation of new corrugated tin which was then aged using repeated applications of MIG Productions standard rust effects.

While I did enjoy building and painting these sheds, the slight detour back to N gauge modelling has confirmed that I'm much happier working at 4mm to the foot scale so I don't think I'll be returning to N gauge at any future point.

I painted the walls and door of the wooden shed using my standard approach for aged wood which has worked well on the OO9 wagons I've recently been building. This seems to work well for N gauge buildings as well. When it came to the roof, however, I wasn't happy with the very flat look of painted brass. To add a little texture I painted it with RailMatch roof dirt and then blew on a small amount of polyfilla while the paint was still wet. Once the paint had dried I then painted it again to cover the white plaster. This seems to have given a nice surface, although I don't think the same would work in 4mm scale as the texture would still be fairly smooth.

I've never tried painting red brick before and the second shed caused quite a few problems. I tried a number of different approaches before I settled on something that mostly worked. In the end I painted the walls with RailMatch dark brick, and then used thinned down RailMatch weathered stone run into the mortar gaps. A final patchy black wash made things look nice and dirty. The corrugated roof was initially painted with roof dirt before a dry brushing of Model Color London grey. This gave a nice approximation of new corrugated tin which was then aged using repeated applications of MIG Productions standard rust effects.

While I did enjoy building and painting these sheds, the slight detour back to N gauge modelling has confirmed that I'm much happier working at 4mm to the foot scale so I don't think I'll be returning to N gauge at any future point.

Wednesday, November 19, 2014

Track Painting

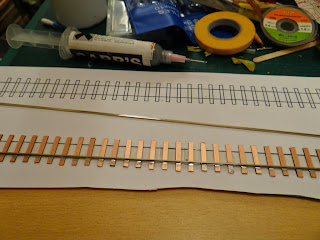

While I was more than happy with my first attempt at track building clearly it needed painting as sleepers are never copper coloured and the rail is never that shiny.

The first job though was to fill the gaps I'd had to file in the sleepers and I did this using some perfect plastic putty from Deluxe Materials which was filed smooth once it had set. The rails were then given a good clean before I tried something new; metal black.

When I built Jerusalem I painted the rails but it wasn't exactly a success. I found that the paint wouldn't stick well to the rails and tended to flake off over time. This time I decided to try using a chemical to blacken the rails instead, specifically I'm using Carr's metal black for nickel silver which I picked up from C&L Finescale along with the track. The health warnings on the bottle were almost enough to put me off using it, but I gently applied it to the rail using cotton wool buds. I was amazed just how quickly it works, but you do have to make sure the rail is very clean as I found any bits that weren’t were impervious to the chemical and stayed shiny. Once I was happy with the colouring I then applied some Carr's Electrofix to seal everything. Electrofix has a misleading name in that it doesn't actually conduct electricity, so I then buffed the railtops using a coffee stirrer which removed the electrofix and some of the blackening to give a used look to the rails. The final step was to paint the sleepers which I did using RailMatch sleeper grime.

Amazingly after all that the rails still conduct power nicely and the locomotive still moves, and I think the whole thing looks much more convincing than the ready-to-run track I was using before.

The first job though was to fill the gaps I'd had to file in the sleepers and I did this using some perfect plastic putty from Deluxe Materials which was filed smooth once it had set. The rails were then given a good clean before I tried something new; metal black.

When I built Jerusalem I painted the rails but it wasn't exactly a success. I found that the paint wouldn't stick well to the rails and tended to flake off over time. This time I decided to try using a chemical to blacken the rails instead, specifically I'm using Carr's metal black for nickel silver which I picked up from C&L Finescale along with the track. The health warnings on the bottle were almost enough to put me off using it, but I gently applied it to the rail using cotton wool buds. I was amazed just how quickly it works, but you do have to make sure the rail is very clean as I found any bits that weren’t were impervious to the chemical and stayed shiny. Once I was happy with the colouring I then applied some Carr's Electrofix to seal everything. Electrofix has a misleading name in that it doesn't actually conduct electricity, so I then buffed the railtops using a coffee stirrer which removed the electrofix and some of the blackening to give a used look to the rails. The final step was to paint the sleepers which I did using RailMatch sleeper grime.

Amazingly after all that the rails still conduct power nicely and the locomotive still moves, and I think the whole thing looks much more convincing than the ready-to-run track I was using before.

Tuesday, November 18, 2014

Go Your Own (Permanent) Way

As Paul was kind enough to turn me a set of brass track gauges I no longer have any excuse for not trying to hand build some OO9 gauge track. Paul has already used his gauges to build a working point, but I decided to start with something a little simpler; a 30cm straight piece of track.

As Paul was kind enough to turn me a set of brass track gauges I no longer have any excuse for not trying to hand build some OO9 gauge track. Paul has already used his gauges to build a working point, but I decided to start with something a little simpler; a 30cm straight piece of track.Of course, deciding to have a go at making my own track was the easy part, working out which parts I was going to use was a bit harder. The easy part was the sleepers. I'm using 3mm wide strips of copper clad PCB cut to a length of approximately 19.25mm (based on a couple of measurements from some PECO stuff I had kicking around). The rail was a lot harder though. The OO9 gauge track I've bought previously uses code 80 rail. The rails are measured in 1/1000's of an inch, so code 80 is 0.080" high. For a light railway this looks a little on the large side and many people use a lighter rail. For example, Paul used code 55 steel rail to build his point, which is 0.055" high. The problem I had was that I wanted to avoid using steel rail as previous experience shows that it does corrode over time, much more so than modern nickel silver rail. In the end I've compromised and used code 60 nickel silver rail from PECO. This rail (PECO IL-1) is a little odd in that it is designed to be used for either Z gauge (which is really tiny) or as conductor rail in 4mm, but it seems perfect for OO9. C&L Finescale stock both the sleepers and the rail and so an order was placed.

Once the parts turned up the first job was to cut the sleepers. The copper clad PCB turns up in strips the right width (3mm) but 17" in length. Fortunately a razor saw cuts through the PCB easily, the problem is how to cut consistent lengths. I could have just measured the strip and marked it up, but I decided I'd make up a little jig to aid the process. This jig sits nicely in my small mitre box and when pushed up against the blade of the razor saw ensures a consistent sleeper length. Once I'd cut a couple of strips into separate sleepers, I then turned to building the track.

I started by drawing up a template on the computer to aid in positioning the sleepers and rails. This was easy for a straight section, but if want to build more complex track in the future will need a little more thought. The sleepers were then stuck to the template using double sided tape, and then the first rail was soldered in place, using coffee stirrers to hold it down while I applied the soldering iron. Once the first rail was soldered to every sleeper I could move on to the tricky bit of adding the second rail.

It turned out that with the track gauges Paul had made me, and some more coffee stirrers, fitting the second rail was nice and straightforward and before long I had something that actually looked like a piece of track. Even better a quick test with a wagon and it looked like it might actually work too. What I'd forgotten to do though was to file a gap into each sleeper to ensure that the rails weren't electrically joined. Fortunately on the straight track it was fairly easy to get a file in between the rails to remove some of the copper; in the future I'll definitely be doing this before I solder the rails down. Finally I removed the track from the template, soldered a wire to each rail and then had a go with letting an actual locomotive run along the track.

I opted to try it out with the small diesel I built from the Narrow Planet kit, as the motor would be a lot easier to replace if everything went wrong than it would on the Quary Hunslet, but fortunately, as you can see, it all worked perfectly. In it's current form the track isn't going to win any beauty contests but it should clean up nicely and now I know that I can at least build plain track which is useable so I'll call that success.

Monday, November 17, 2014

Jiggery-Pokery

Given how much "fun" people had guessing the use for a pile of plastic tagliatelle I thought I'd show you the small jig I've just put together to help with another modelling task. So does anyone know what I'm using this for?

Saturday, November 15, 2014

Canopus: Three Out of Four Ain't Bad

Just a short update on Canopus today. If you remember the last time we saw Canopus I'd fixed the retaining nuts for the coupling rods on using threadlocker and everything still seemed to work. Well today I've gone one step further and trimmed the crank pins and filed down the retaining nuts. Amazingly it all still works.

Just a short update on Canopus today. If you remember the last time we saw Canopus I'd fixed the retaining nuts for the coupling rods on using threadlocker and everything still seemed to work. Well today I've gone one step further and trimmed the crank pins and filed down the retaining nuts. Amazingly it all still works.I did have one small problem in that one of the four retaining nuts came loose once I'd filed it down. I'm guessing I'd not got the threadlocker all the way along the thread. Worse when trying to reattach it, the now very thin nut, went pinging off across my study, destination unknown. With some difficulty I managed to get a new nut on to the tiny remaining crank pin along with lots of threadlocker. I then filed this nut down. Unfortunately once filed down it was also loose, so this one has been soldered in place.

Wednesday, November 12, 2014

A Tiny Brick Shed

Okay, so I'm easily seduced by shiny brass models.

This one went together just as easily as the wooden shed. I haven't started painting either of them yet as I haven't been at home when it hasn't been raining so I've been unable to spray them with primer. Hopefully the weather will improve and I can finish these off soon. I did, however, pick up a pot of RailMath Dark Brick (#2424) on the way home so I think I now have the paints I need to paint both models.

This one went together just as easily as the wooden shed. I haven't started painting either of them yet as I haven't been at home when it hasn't been raining so I've been unable to spray them with primer. Hopefully the weather will improve and I can finish these off soon. I did, however, pick up a pot of RailMath Dark Brick (#2424) on the way home so I think I now have the paints I need to paint both models.

Tuesday, November 11, 2014

A Tiny Wooden Shed

So here we have the first of the two sheds from the Severn Models kit I showed you yesterday. As expected it went together nice and easily. I soldered everything but the barge boards (just too fiddly) even though the instructions say to just use glue. In retrospect I think this was a good idea as I had problems with the barge boards as the superglue took an awful long time to grab properly. As you can see it really is tiny, given that it's sat on a 50p piece.

So that's half the kit built (there is the brick shed to go) and I think we can agree it builds up into a nice model. I'll paint this one next before building the other shed, as I know how to paint old looking wood, but I've no idea how to go about painting brick work.

So that's half the kit built (there is the brick shed to go) and I think we can agree it builds up into a nice model. I'll paint this one next before building the other shed, as I know how to paint old looking wood, but I've no idea how to go about painting brick work.

Monday, November 10, 2014

A House in Your Hand

A shiny new brass kit fell through the letterbox today. Given that I've shifted to modelling at 4mm to the foot scale from the 2mm scale of N gauge and have now boxed up and stored Jerusalem in the loft (to make way for me as yet unannounced new OO9 gauge layout) you may be surprised to see that it is in fact an N gauge kit.

I didn't actually buy this kit in the normal sense of the verb "to buy". This is actually a reward for backing a crowd funding project on Kickstarter. Specifically the project aimed at developing a number of etched brass building kits for N gauge model railways with the tag line being "A House in Your Hand". Now while there was the option of lots of lovely kits for large buildings, given that I wasn't modelling in N gauge at the moment, I went for the cheaper option of a kit for two small sheds, as a way of getting something to play with while showing my support for the project.

Now you do have to be careful with Kickstarter projects, in that you are essentially putting up money to fund the development of something that might not turn out to be feasible. There have been some projects that have raised huge amounts of money yet failed to deliver on their promises, so it really is buyer beware. My rule of thumb is never back a project for more money than you would be willing to write off. So far I've backed 10 projects and four have delivered. Five of them have completion dates in the future but one, in fact the first project I backed, should have finished in January, so is at least 8 months behind schedule. This was also an N gauge related project, but I'm now sceptical that it will ever grace this blog. Anyway back to this kit...

First impressions are that the etching looks great, although the instructions are a little thin. There is a side of A4 telling you general things about building brass kits (they suggest superglue but I think I'll solder for added strength), and then two exploded diagrams one for each shed. Unfortunately in a couple of places the orientation of some parts (barge boards mostly) is a little unclear, although I think once I actually try to assemble it things will become more obvious.

Currently the kits aren't publicly available to buy, but a website for Severn Models is under construction so hopefully that will change shortly. While I have no immediate use for these sheds I'll be assembling and painting them when I get a chance so I'll let you know how I get on.

I didn't actually buy this kit in the normal sense of the verb "to buy". This is actually a reward for backing a crowd funding project on Kickstarter. Specifically the project aimed at developing a number of etched brass building kits for N gauge model railways with the tag line being "A House in Your Hand". Now while there was the option of lots of lovely kits for large buildings, given that I wasn't modelling in N gauge at the moment, I went for the cheaper option of a kit for two small sheds, as a way of getting something to play with while showing my support for the project.

Now you do have to be careful with Kickstarter projects, in that you are essentially putting up money to fund the development of something that might not turn out to be feasible. There have been some projects that have raised huge amounts of money yet failed to deliver on their promises, so it really is buyer beware. My rule of thumb is never back a project for more money than you would be willing to write off. So far I've backed 10 projects and four have delivered. Five of them have completion dates in the future but one, in fact the first project I backed, should have finished in January, so is at least 8 months behind schedule. This was also an N gauge related project, but I'm now sceptical that it will ever grace this blog. Anyway back to this kit...

First impressions are that the etching looks great, although the instructions are a little thin. There is a side of A4 telling you general things about building brass kits (they suggest superglue but I think I'll solder for added strength), and then two exploded diagrams one for each shed. Unfortunately in a couple of places the orientation of some parts (barge boards mostly) is a little unclear, although I think once I actually try to assemble it things will become more obvious.

Currently the kits aren't publicly available to buy, but a website for Severn Models is under construction so hopefully that will change shortly. While I have no immediate use for these sheds I'll be assembling and painting them when I get a chance so I'll let you know how I get on.

Sunday, November 9, 2014

Canopus: Biting The Bullet

So I've finally bitten the bullet and permanently attached the coupling rods on Canopus. The good news is that everything still seems to turn freely under power so it doesn't look like I've messed anything up..... phew!

The instructions say to use solder to affix the retaining nuts in place. Experience from building the Quarry Hunslet suggests this doesn't work very well. The problem is that you need to fix the nut before snipping off the excess pin and filling the nut thickness down. When soldering the nuts the solder doesn't penetrate all the way through the nut which means when you start filling it down the first thing you do is file off the solder and the nut becomes loose. On the Quarry Hunslet I secured the coupling rod in place with superglue but still found this difficult as you get so little time to check and adjust things.

For Canopus I took a slightly different approach and have used LOCTITE 243 medium strength threadlocker. This gives me (according to the datasheet) 5 minutes fixture time (that's for brass, it's 10 minutes for stainless steel). Also unlike superglue it is designed to be reversible, assuming you can supply 26 Newton-metres of torque. I used a slip of paper to try and stop the stuff getting anywhere it shouldn't as well as ensuring that I didn't over-tighten the nuts. This seems to have worked well although removing the last bits of paper was a bit of a pain.

I haven't yet removed the excess crank pin or filled down the nut (this was as much stress as I wanted today) but having had it on the rolling rod everything seems to be working nicely. You can tell that the threadlocker is working as previously running in one direction would cause the nuts to work loose which is no longer happening. Now I've got past this point hopefully progress will pick up a little.

The instructions say to use solder to affix the retaining nuts in place. Experience from building the Quarry Hunslet suggests this doesn't work very well. The problem is that you need to fix the nut before snipping off the excess pin and filling the nut thickness down. When soldering the nuts the solder doesn't penetrate all the way through the nut which means when you start filling it down the first thing you do is file off the solder and the nut becomes loose. On the Quarry Hunslet I secured the coupling rod in place with superglue but still found this difficult as you get so little time to check and adjust things.

For Canopus I took a slightly different approach and have used LOCTITE 243 medium strength threadlocker. This gives me (according to the datasheet) 5 minutes fixture time (that's for brass, it's 10 minutes for stainless steel). Also unlike superglue it is designed to be reversible, assuming you can supply 26 Newton-metres of torque. I used a slip of paper to try and stop the stuff getting anywhere it shouldn't as well as ensuring that I didn't over-tighten the nuts. This seems to have worked well although removing the last bits of paper was a bit of a pain.

I haven't yet removed the excess crank pin or filled down the nut (this was as much stress as I wanted today) but having had it on the rolling rod everything seems to be working nicely. You can tell that the threadlocker is working as previously running in one direction would cause the nuts to work loose which is no longer happening. Now I've got past this point hopefully progress will pick up a little.

Dry Stone Walling

Some of you may remember that back in March I built a couple of short sections of stone walling using brick papers from scalescenes.com. The first attempt was wrong as the stones were too big, and while the second attempt was better, the wall was just too flat with no relief. Having now abandoned brick papers for full structures in favour of embossed plastikard I decided I needed to have another go at building a stone wall. The result is this little test piece (using the driver from the Brian Madge Quarry Hunslet kit to give a sense of scale).

Personally I think this looks an order of magnitude better than my previous attempts. It did, however, taken an order of magnitude longer to produce as well. In fact that short piece of wall took all day, although some of that was waiting for DAS clay to dry. What you are looking at is a wall where each stone was cut and laid separately to produce a dry stone wall; albeit with PVA to keep the stones in place.

The technique I've used is based on Ian Nuttall's description of how he built dry stone walls for his layout (February 2013 edition of Railway Modeller). The idea is to create 6mm wide strips of DAS clay of varying heights that can be cut to make individual stones and used to model a 1' 6" wide wall. Rolling, measuring and and cutting DAS clay to the right sizes would be a pain, which is where the plastic tagliatelle comes in to play.

I built a jig from a sheet of 2mm plastikard and various sized square sections of plastruct. I used 1.5mm, 2mm, 2.5mm, 3.2mm, and 4mm sections to give five channels 6mm wide allowing me to model stones 4 1/2", 6", 7 1/2", 9 2/3" and 1' tall by simply pushing DAS into the channels of the jig. The problem is removing the DAS from the jig. The trick here is to place one of the plastic strips at the bottom of the channel, then add the DAS, and then just lift the plastic strip to remove the clay. Once the DAS has dried the plastic strip peels off easily and can be reused.

Once the clay strips have dried (I should possibly have left them a little longer but I was getting inpatient) they can be cut into individual stones; I found my track cutters worked really well for this bit. The wall is started by laying down a thin ribbon of PVA and placing the first course of stones. Small dabs of PVA are then used to add the further layers trying to avoid any leaking out the side of a join. I aimed for a level topped four foot high wall, before then adding the capping stones, which were slightly rounded, to give a wall approximately 4' 6" high. This seems to look about right next to the figure.

I painted the wall initially with RailMatch weathered stone (#2426) before giving the whole thing a black wash making sure to get the wash deep into the cracks where the base coat hadn't necessarily flowed. I then lightly dry brushed more weathered stone and some khaki (Model Color #988) to add a little variation. The final touch (which is mostly hidden behind the greenery) was to dry brush a little brown sand (Model Color #876) along the bottom of the wall to represent dirt having splashed up.

While the wall looked good at that point (I forgot to take any photos) I thought it was worth adding more scenery to see how it would look in the context of a layout rather than in isolation. I used some cheap burnt umber acrylic (I bought a large tube ages ago from WH Smiths) to provide a base colour and to hide the white cardboard. I then used Woodland Scenics green blend blended turf to provide ground cover before adding various shades of Woodland Scenics bushes and foliage clumps for bushes around the wall edges. The final touch was a little bit of yellow flowering foliage to the right side to add more colour.

Hopefully you will all agree that this looks a lot better than my previous brick paper attempts at making walls. Having said that it still isn't perfect, mostly as I think the proportion of large stones in the wall is too high; locally the walls are mostly small stones rather than large chunks. Changing the proportion of stone sizes though is easy so I think this is another scenic technique that I'm now happy with so another piece of the puzzle falls into place.

Personally I think this looks an order of magnitude better than my previous attempts. It did, however, taken an order of magnitude longer to produce as well. In fact that short piece of wall took all day, although some of that was waiting for DAS clay to dry. What you are looking at is a wall where each stone was cut and laid separately to produce a dry stone wall; albeit with PVA to keep the stones in place.

The technique I've used is based on Ian Nuttall's description of how he built dry stone walls for his layout (February 2013 edition of Railway Modeller). The idea is to create 6mm wide strips of DAS clay of varying heights that can be cut to make individual stones and used to model a 1' 6" wide wall. Rolling, measuring and and cutting DAS clay to the right sizes would be a pain, which is where the plastic tagliatelle comes in to play.

I built a jig from a sheet of 2mm plastikard and various sized square sections of plastruct. I used 1.5mm, 2mm, 2.5mm, 3.2mm, and 4mm sections to give five channels 6mm wide allowing me to model stones 4 1/2", 6", 7 1/2", 9 2/3" and 1' tall by simply pushing DAS into the channels of the jig. The problem is removing the DAS from the jig. The trick here is to place one of the plastic strips at the bottom of the channel, then add the DAS, and then just lift the plastic strip to remove the clay. Once the DAS has dried the plastic strip peels off easily and can be reused.

Once the clay strips have dried (I should possibly have left them a little longer but I was getting inpatient) they can be cut into individual stones; I found my track cutters worked really well for this bit. The wall is started by laying down a thin ribbon of PVA and placing the first course of stones. Small dabs of PVA are then used to add the further layers trying to avoid any leaking out the side of a join. I aimed for a level topped four foot high wall, before then adding the capping stones, which were slightly rounded, to give a wall approximately 4' 6" high. This seems to look about right next to the figure.

I painted the wall initially with RailMatch weathered stone (#2426) before giving the whole thing a black wash making sure to get the wash deep into the cracks where the base coat hadn't necessarily flowed. I then lightly dry brushed more weathered stone and some khaki (Model Color #988) to add a little variation. The final touch (which is mostly hidden behind the greenery) was to dry brush a little brown sand (Model Color #876) along the bottom of the wall to represent dirt having splashed up.

While the wall looked good at that point (I forgot to take any photos) I thought it was worth adding more scenery to see how it would look in the context of a layout rather than in isolation. I used some cheap burnt umber acrylic (I bought a large tube ages ago from WH Smiths) to provide a base colour and to hide the white cardboard. I then used Woodland Scenics green blend blended turf to provide ground cover before adding various shades of Woodland Scenics bushes and foliage clumps for bushes around the wall edges. The final touch was a little bit of yellow flowering foliage to the right side to add more colour.

Hopefully you will all agree that this looks a lot better than my previous brick paper attempts at making walls. Having said that it still isn't perfect, mostly as I think the proportion of large stones in the wall is too high; locally the walls are mostly small stones rather than large chunks. Changing the proportion of stone sizes though is easy so I think this is another scenic technique that I'm now happy with so another piece of the puzzle falls into place.

Saturday, November 8, 2014

Plastic Tagliatelle

Just a little teaser for today's post. I spent a bit of time yesterday cutting a plastic food bag into strips 6mm wide by about 29cm long (the width of the bag). These will be used to help with a specific bit of scenic modelling. Anyone fancy a guess at what?

Friday, November 7, 2014

Track Gauges

Today saw the arrival in the post of these two excellent OO9 track gauges. Some of you will have already seen these, as they were turned for me by Paul and he has already blogged about how he made them.

I'd recently started a discussion over on the Narrow Gauge Railway Modelling forum about forming tight curves (unfortunately you need to be a member to read this), and a number of people suggested that instead of trying to tightly bend flexitrack I should instead build my own track. The problem was that I had no idea what height of rail I wanted to use and all the commercial track gauges are designed for specific rail types. Paul suggested that he could easily turn a set of gauges that could be used with any height of rail, and so we now both have a set of OO9 track gauges, and will both be having a go at building some track (the photo shows them sat on some standard PECO crazy track).

I'm going to start with some plain track, although Paul says he might start with a point. Given the fun I've had getting good running through shop bought points, I'll definitely not be building my own just yet, but plain track seems doable.

While the track will be OO9 it won't be for the mythical 77 Box Lane layout, as I'm still not entirely happy with the track plan. I do, however, have a new track plan in mind that will allow me scope to practice track laying and more scratch-building of structures. That plan though will wait for another post.

Thanks again Paul, hopefully the track will look half as good as the track gauges!

I'd recently started a discussion over on the Narrow Gauge Railway Modelling forum about forming tight curves (unfortunately you need to be a member to read this), and a number of people suggested that instead of trying to tightly bend flexitrack I should instead build my own track. The problem was that I had no idea what height of rail I wanted to use and all the commercial track gauges are designed for specific rail types. Paul suggested that he could easily turn a set of gauges that could be used with any height of rail, and so we now both have a set of OO9 track gauges, and will both be having a go at building some track (the photo shows them sat on some standard PECO crazy track).

I'm going to start with some plain track, although Paul says he might start with a point. Given the fun I've had getting good running through shop bought points, I'll definitely not be building my own just yet, but plain track seems doable.

While the track will be OO9 it won't be for the mythical 77 Box Lane layout, as I'm still not entirely happy with the track plan. I do, however, have a new track plan in mind that will allow me scope to practice track laying and more scratch-building of structures. That plan though will wait for another post.

Thanks again Paul, hopefully the track will look half as good as the track gauges!

Wednesday, November 5, 2014

Hay Wagon

The mathematically inclined amongst you may have spotted that in yesterday's post I mentioned that I'd printed eight underframes but only four bodies of the Sand Hutton wagons. This wasn't because I wanted a surplus of underframes but because I'd also printed a second set of parts. While there are no drawings provided, and only two blurry photos, the book describes a wood frame 16 ft long and 6 ft wide that was fitted to two underframes and used to carry 70 trusses of hay.

Obviously with so little detail to go on I'm not sure how accurate this model is, but it clips nicely to two of the underframes and once I've figured out how to model 70 trusses of hay will be well hidden anyway.

Obviously with so little detail to go on I'm not sure how accurate this model is, but it clips nicely to two of the underframes and once I've figured out how to model 70 trusses of hay will be well hidden anyway.

Tuesday, November 4, 2014

A Partial Success

Today saw the delivery of my most recent 3D print order from Shapeways which contained the Sand Hutton wagons you've recently seen me design. Unfortunately the models were not quite as much of a success as I would have liked, although I don't think the problem is with the 3D model, but we'll get to that later. Let's start by showing you the wagon in it's two basic forms; sorry that the photos aren't very clear but the translucent nature of the prints makes them a nightmare to photograph.

One of the main features of these wagons was that the body could be lifted clear of the underframe (hence the four lifting eyes) and so I modelled the two parts separately. As you can see they fit together quite nicely and they look the part. So far so good. The problem is that what you are seeing here is a bit of a cheat.

Firstly, I should admit that I tried to be clever with this model and that has at least contributed to the problems. In reality both sides of the wagon were hinged to allow easy access to the contents, and I decided to try and model that. My plan was to use 0.2mm nickel silver rod not only to add some of the fine details but also to act as a hinge allowing the side doors to open. In the photo above I've actually glued the sides in place so that I can check the look of the model, as I can't get the nickel silver rod through the holes in the parts. I think this is actually just because I can't clean them out properly and while I thought I had a 0.2mm drill I don't (my smallest is 0.3mm) so until the ones I've ordered arrive I have resorted to glue; something I was going to try anyway as not everyone will want the hassle of fitting the hinges.

Now I grouped the wagons into a number of models when I placed the order, and in total ordered four wagon bodies and eight underframes. Unfortunately when the prints arrived three of the bodies were broken and four of the underframes were also broken. In this photo you can see a complete body and underframe on the left, and then a broken body, and a broken underframe.

Initially I thought the wagon bodies might have broken simply because the sprue I'd used wasn't thick enough. looking closely though it is clear that there is no break and I think what has happened is that Shapeways have deliberately cut the model into two parts for some reason. Given that they placed the break on a sprue it is annoying (I paid for the sprue material which I didn't need to add if they are going to break it) but doesn't render the part unusable (although the support material has ended up in a different orientation than I expected which has obscured some details). The underframes though are a different matter.

The underframes have again been broken into two, and this must have happened prior to printing as the axle boxes, which are joined by the sprue containing the coupling hooks) have been cleanly separated from the rest of the frame. This can't have been accidental. Unfortunately this means I'd have to glue the axle boxes in place and I doubt the model would be very strong as a result. It's unclear why this has happened, especially as some of the parts printed perfectly, but I'm assuming it was human intervention in some way. I've got a complaint in to Shapeways about this as they shouldn't be breaking models at arbitrary points as clearly they won't know what is functional and what is sprue material etc. Hopefully I'll get a sensible answer, but I'll be asking for a refund rather than a reprint while I check the hinges and finalize other details. What this means of course is that these models won't be available for a while as I can't run the risk of them being misprinted for anyone else.

I'll get this model painted up at some point, and when the 0.2mm drills arrive I'll see how the hinges work (if at all), before tweaking the 3D model and trying for a second prototype print.

One of the main features of these wagons was that the body could be lifted clear of the underframe (hence the four lifting eyes) and so I modelled the two parts separately. As you can see they fit together quite nicely and they look the part. So far so good. The problem is that what you are seeing here is a bit of a cheat.

Firstly, I should admit that I tried to be clever with this model and that has at least contributed to the problems. In reality both sides of the wagon were hinged to allow easy access to the contents, and I decided to try and model that. My plan was to use 0.2mm nickel silver rod not only to add some of the fine details but also to act as a hinge allowing the side doors to open. In the photo above I've actually glued the sides in place so that I can check the look of the model, as I can't get the nickel silver rod through the holes in the parts. I think this is actually just because I can't clean them out properly and while I thought I had a 0.2mm drill I don't (my smallest is 0.3mm) so until the ones I've ordered arrive I have resorted to glue; something I was going to try anyway as not everyone will want the hassle of fitting the hinges.

Now I grouped the wagons into a number of models when I placed the order, and in total ordered four wagon bodies and eight underframes. Unfortunately when the prints arrived three of the bodies were broken and four of the underframes were also broken. In this photo you can see a complete body and underframe on the left, and then a broken body, and a broken underframe.

Initially I thought the wagon bodies might have broken simply because the sprue I'd used wasn't thick enough. looking closely though it is clear that there is no break and I think what has happened is that Shapeways have deliberately cut the model into two parts for some reason. Given that they placed the break on a sprue it is annoying (I paid for the sprue material which I didn't need to add if they are going to break it) but doesn't render the part unusable (although the support material has ended up in a different orientation than I expected which has obscured some details). The underframes though are a different matter.

The underframes have again been broken into two, and this must have happened prior to printing as the axle boxes, which are joined by the sprue containing the coupling hooks) have been cleanly separated from the rest of the frame. This can't have been accidental. Unfortunately this means I'd have to glue the axle boxes in place and I doubt the model would be very strong as a result. It's unclear why this has happened, especially as some of the parts printed perfectly, but I'm assuming it was human intervention in some way. I've got a complaint in to Shapeways about this as they shouldn't be breaking models at arbitrary points as clearly they won't know what is functional and what is sprue material etc. Hopefully I'll get a sensible answer, but I'll be asking for a refund rather than a reprint while I check the hinges and finalize other details. What this means of course is that these models won't be available for a while as I can't run the risk of them being misprinted for anyone else.

I'll get this model painted up at some point, and when the 0.2mm drills arrive I'll see how the hinges work (if at all), before tweaking the 3D model and trying for a second prototype print.

Sunday, October 26, 2014

The Rails Were For...

All the way back in May of 2013, I blogged about the odd set of narrow rails you could see if you visited my local DIY shop. Unfortunately the road has since been resurfaced and the rails can no longer be seen.

The DIY shop is housed in what was, according to old maps, a wagon and wheel works and in the previous post I speculated that, for want of any other information, that the rails might relate to some form of travelling crane. Well I was wrong.

I've now, thanks to issue 190 of the Industrial Railway Record, that the works were the premises of William Gittus & Son Ltd. It appears that in general most of the work involved repairing wagons rather than building new ones, but they had a very distinctive builders plate featuring a dog which they attached to the wagons they worked on.

While it is nice to be able to put a name to the company that ran the works, the article also clears up the issue of the rails...

The DIY shop is housed in what was, according to old maps, a wagon and wheel works and in the previous post I speculated that, for want of any other information, that the rails might relate to some form of travelling crane. Well I was wrong.

I've now, thanks to issue 190 of the Industrial Railway Record, that the works were the premises of William Gittus & Son Ltd. It appears that in general most of the work involved repairing wagons rather than building new ones, but they had a very distinctive builders plate featuring a dog which they attached to the wagons they worked on.

While it is nice to be able to put a name to the company that ran the works, the article also clears up the issue of the rails...

by 1905 several developments had taken place ... a large wooden building (which could accommodate six wagons and was known to the workmen as the "big shed") was constructed on the west side of the dike. The big shed had a full length traverser at it's west end and was served by four sidings. ... Further expansion took place in the 1920s when extensions were made to the Big Shed and a second similar sized building was erected on its west side. The traverser was then situated between the two shops and two horses were employed to shunt in this area.So we now have a definitive answer, the rails were the remains of the wagon traverser.

Saturday, October 25, 2014

To The Printers!

While the only difference from the previous post is the addition of a few bolts around the coupling hook I thought it was worth sharing a nice large rendering of the final model of the Sand Hutton wagon.

I've now broken the model down into a few separate parts (body, underframe, coupling hook, etc.) and have ordered a couple of prints. It usually takes just over a week for the prints to arrive so I'll just have to find some other modelling to fill the time until then. Maybe I'll finally get around to finishing the coupling rods on Canopus, or maybe I'll get distracted by something else. You'll just have to wait and see.

I've now broken the model down into a few separate parts (body, underframe, coupling hook, etc.) and have ordered a couple of prints. It usually takes just over a week for the prints to arrive so I'll just have to find some other modelling to fill the time until then. Maybe I'll finally get around to finishing the coupling rods on Canopus, or maybe I'll get distracted by something else. You'll just have to wait and see.

Thursday, October 23, 2014

Dumb and Dumber

I've still not quite finished the Sand Hutton wagon but I think there are just a few bolts left before it will be ready for printing. The main new items today are the rounded dumb buffers and the coupling hook. Both of these were produced by tracing the part from the original works drawing.

Whilst we now know that the drawing isn't particularly accurate the depiction of the buffers and coupling hooks seem to match the photos quite well so this seemed the best way to model them and I think they've turned out nicely. The coupling hook is interesting as I've actually modelled it as a separate part.

On the printed model there will be a slot in the buffer beam to take a Greenwich coupling (the slot will actually be about 0.5mm too low due to the low slung nature of the wagon so the coupling shank will need bending a little to compensate), there will also be a sprue containing coupling hooks attached to a plate, which should fit the slot perfectly, for those people who would prefer a prototypical looking hook rather than a working coupling. These are going to be tiny parts so I've no idea how well they'll turn out until I get a print in my hands.

Whilst we now know that the drawing isn't particularly accurate the depiction of the buffers and coupling hooks seem to match the photos quite well so this seemed the best way to model them and I think they've turned out nicely. The coupling hook is interesting as I've actually modelled it as a separate part.

On the printed model there will be a slot in the buffer beam to take a Greenwich coupling (the slot will actually be about 0.5mm too low due to the low slung nature of the wagon so the coupling shank will need bending a little to compensate), there will also be a sprue containing coupling hooks attached to a plate, which should fit the slot perfectly, for those people who would prefer a prototypical looking hook rather than a working coupling. These are going to be tiny parts so I've no idea how well they'll turn out until I get a print in my hands.

Tuesday, October 21, 2014

Axle Boxes

Progress on the wagon from the Sand Hutton Light Railway is slow but steady. As with physical modelling, building the rough structure is relatively quick but adding the details, especially odd shaped ones, takes a disproportionate amount of time and effort.

I've had a bit of a rethink about which bits are printable and which aren't and so a few more details have been added to the body of the wagon. I'm probably going to print a couple of different versions of the wagon with different levels of detail parts to see what works and what needs to be modelled in some other way than printing. The main obvious difference to the body are the lifting straps which, after ignoring the works drawings, and looking at photos I've decided may be printable after all. These were easy to add so it makes sense to experiment with them.

Having finished detailing the body I've also started on the underframe, specifically the axle boxes. The axles boxes on these wagons are unusual in that they are cast in pairs. It's difficult to tell exactly what shape they are from the drawings or from the photos (they tend to be in shadow under the underframe) so I've made a number of guesses. Hopefully given their small size they will at least "look right". Now I just have to finish adding all the bolts to the underframe and to round the dumb buffers and then I should be ready to order a prototype print or two.

I've had a bit of a rethink about which bits are printable and which aren't and so a few more details have been added to the body of the wagon. I'm probably going to print a couple of different versions of the wagon with different levels of detail parts to see what works and what needs to be modelled in some other way than printing. The main obvious difference to the body are the lifting straps which, after ignoring the works drawings, and looking at photos I've decided may be printable after all. These were easy to add so it makes sense to experiment with them.

Having finished detailing the body I've also started on the underframe, specifically the axle boxes. The axles boxes on these wagons are unusual in that they are cast in pairs. It's difficult to tell exactly what shape they are from the drawings or from the photos (they tend to be in shadow under the underframe) so I've made a number of guesses. Hopefully given their small size they will at least "look right". Now I just have to finish adding all the bolts to the underframe and to round the dumb buffers and then I should be ready to order a prototype print or two.

Sunday, October 19, 2014

One for the Rivet Counters

Given that I now know that both the original works drawings and the modern scale drawings don't accurately reflect the wagons that were actually used on the Sand Hutton light Railway, I've had to take a few liberties with some aspects of construction. Specifically I've been unable to locate any photos showing the inside of the wagons in any detail. This means that the placement of some of the bolts, especially those in the floor have had to be estimated. It's also unclear if the end walls had metal strapping on the inside. Photos of the wagons at Deptford supply depot, clearly show strapping, but on other photos it is less clear. I've decided to add the strapping (inset into the planks as on the side doors) given that the clearest photos show it to be present even if it isn't on the works drawings. Anyway the following render shows the progress I've made today.