It's now been a month since I last posted and over a month since I last did any modelling. This isn't for lack of interest but rather a serious lack of time. This is unlikely to change in the foreseeable future either, so you can expect posts to be slightly more sporadic than usual.

Some of you already know why I've been busy, but many of you won't so here is a clue....

That photo was taken on Sunday when I introduced my three week old son, Toby Arthur, to his first steam train -- I didn't even have to go far as this was another running of the Tin Bath railtour along the line at the bottom of our garden (see here and here for more details)

At the moment any "free" time I might have is probably going to be spent catching up on sleep so it's unlikely I'll get much modelling done for at least a few months. I'm also probably going to be more careful about the use of paints and chemicals in the house so some things may need to wait for me to tidy the garage and for some warmer weather (there is a light covering of snow outside as I type this). That being said I've got a couple of new models I'd like to have a go at designing and some articles to write, both of which I can do on my laptop in short bursts of a few minutes here and there between nappy changes and cuddles.

Of course there is also a flip side to all this, in that as he grows up I'm hoping I'll be able to interest him in trains which would mean days out to preserved railways, train sets (as opposed to model railways), as well as models I could build him. Clearly having called him Toby I'm going to need to build an LNER J70 at some point, and while only a minor character maybe I'll need to find an Ivatt 2MT 2-6-2T as well. Before we get to Thomas the Tank Engine though I'm going to start by reading him Ivor the Engine from a book that was read to me when I was small, plus I've always fancied building a model of Ivor.

Wednesday, November 9, 2016

Sunday, October 9, 2016

Figure Painting

So in the previous post I mentioned I'd used a new painting method. Technically it's not new, but it's not something I'd tried before and that is stain painting to colour the figures.

All the figure painting I've done in the past (either recently or when painting Games Workshop figures in my misspent youth) has followed the same approach of block painting colours and then either picking out the highlights with dry brushing or emphasizing creases using thin washes. The problem is that this can be quite time consuming and more importantly finding complimentary colours for highlights and washes can be tricky. This new, for me, approach inverts this process. If you want lots of details then I followed the suggestions on this web page, but essentially you can see the whole process in these four photos.

The first step is simply to paint the entire figure black. This is followed by dry brushing with white to pick out the highlights. Colours are then added using paint diluted with water (to a consistency like milk). Rather than completely covering the underlying areas this essentially stains the lower layers allowing the creases and highlights to show through. A quick waft of matt varnish to helps tie everything together to give...

This is of course a rather cruel close up being many times life size, but you get the general idea. As I said at the start it's not a new idea, but was something I've never tried before, but from this brief test will be something I'll be doing a lot more in the future.

All the figure painting I've done in the past (either recently or when painting Games Workshop figures in my misspent youth) has followed the same approach of block painting colours and then either picking out the highlights with dry brushing or emphasizing creases using thin washes. The problem is that this can be quite time consuming and more importantly finding complimentary colours for highlights and washes can be tricky. This new, for me, approach inverts this process. If you want lots of details then I followed the suggestions on this web page, but essentially you can see the whole process in these four photos.

The first step is simply to paint the entire figure black. This is followed by dry brushing with white to pick out the highlights. Colours are then added using paint diluted with water (to a consistency like milk). Rather than completely covering the underlying areas this essentially stains the lower layers allowing the creases and highlights to show through. A quick waft of matt varnish to helps tie everything together to give...

This is of course a rather cruel close up being many times life size, but you get the general idea. As I said at the start it's not a new idea, but was something I've never tried before, but from this brief test will be something I'll be doing a lot more in the future.

Friday, October 7, 2016

A Display Model

While I've painted numerous models for myself, one of which even did well in a competition, and built a model as a commission, until recently one thing I hadn't done was produce a display model. As I won't be going to ExpoNG this year and I didn't fancy risking any of my completed Hudson-Hunslet models in the post, I decided it would be good to have a display model that people could see on the Narrow Planet stand to entice them into buying a kit.

As a display model it doesn't need to work so it doesn't contain a motor or layshaft etc. This is partly as I built it around a misprinted brass chassis that won't hold the layshaft, as well as some gears on the axles that I damaged during building of the first prototype model. Of course none of that matters when it's simply being viewed on the display stand. So if you haven't had the chance to see one of these Hudson-Hunslet models in the flesh yet, have a day out at ExpoNG and hunt out the Narrow Planet stand for a good look.

As well as being fun to build I also experimented with a new painting technique but that can wait for another post.

As a display model it doesn't need to work so it doesn't contain a motor or layshaft etc. This is partly as I built it around a misprinted brass chassis that won't hold the layshaft, as well as some gears on the axles that I damaged during building of the first prototype model. Of course none of that matters when it's simply being viewed on the display stand. So if you haven't had the chance to see one of these Hudson-Hunslet models in the flesh yet, have a day out at ExpoNG and hunt out the Narrow Planet stand for a good look.

As well as being fun to build I also experimented with a new painting technique but that can wait for another post.

Friday, September 2, 2016

Lamp Brackets

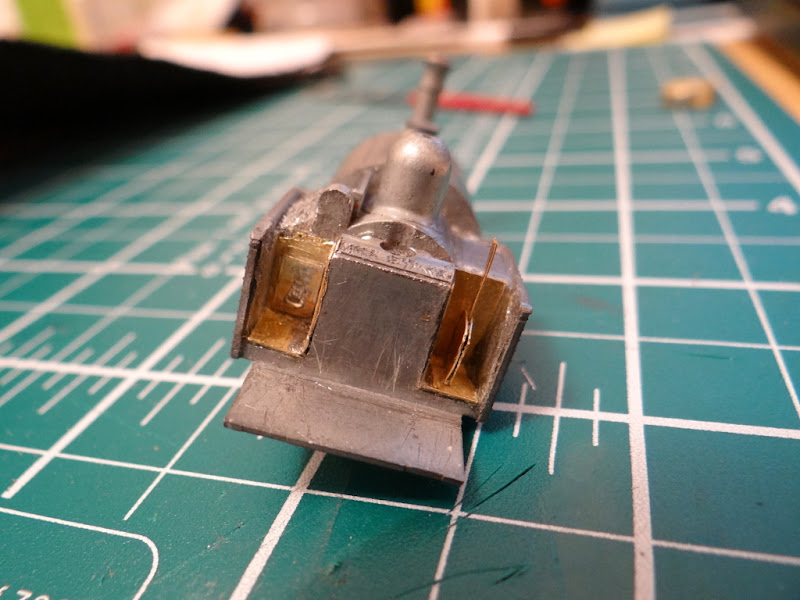

With all the pipework now sorted I think I'm down to the last two details I need to finish before I can think about painting; lamp brackets and the smokebox door. The smokebox door will be covered in another post but today I've fabricated the lamp brackets and fitted the rear one.

The original cab moulding had empty lamp brackets at both the botom corners of the rear sheet, and a lamp in the middle just below the windows. I wasn't happy with any of these and so they were all removed quite early on. Having looked at old photos I've settled on a single lamp bracket on the rear of the cab, and as you can see have used a whitemetal casting for the lamp itself (this is actually a 3mm scale casting from 3mm Scale Model Railways). Of course the loco would usualy only carry a single lamp positioned at the front or rear depending on which way it was travelling, so I've made the lamp removable so in theory it can move between the rear and front lamp brackets.

Here you can see the fitted bracket, along with the lamp (modified with a locating loop), and the tool I made to form the brackets. The tool is simply a piece of brass with a slot in it, but it allows you to easily bend a strip of brass for the brackets. Not much to show I know but I think it's a nice feature. I might find I glue the lamp on because it's more hassle than it's worth but for now having the ability to remove it should be a nice touch.

The original cab moulding had empty lamp brackets at both the botom corners of the rear sheet, and a lamp in the middle just below the windows. I wasn't happy with any of these and so they were all removed quite early on. Having looked at old photos I've settled on a single lamp bracket on the rear of the cab, and as you can see have used a whitemetal casting for the lamp itself (this is actually a 3mm scale casting from 3mm Scale Model Railways). Of course the loco would usualy only carry a single lamp positioned at the front or rear depending on which way it was travelling, so I've made the lamp removable so in theory it can move between the rear and front lamp brackets.

Here you can see the fitted bracket, along with the lamp (modified with a locating loop), and the tool I made to form the brackets. The tool is simply a piece of brass with a slot in it, but it allows you to easily bend a strip of brass for the brackets. Not much to show I know but I think it's a nice feature. I might find I glue the lamp on because it's more hassle than it's worth but for now having the ability to remove it should be a nice touch.

Wednesday, August 31, 2016

Pipework

After a lot of hunting through old photos (thanks to everyone who helped me find them all) I finally managed to get enough of an idea about the pipework alongside the dome to produce a passable representation.

It's not perfect but from normal viewing distances I think it will do the job nicely.

It's not perfect but from normal viewing distances I think it will do the job nicely.

Monday, July 25, 2016

No Such Thing As Bad Publicity?

Over the last couple of months my modelling has been featured, one way or another, in three different magazines. First up was the June issue of British Railway Modelling, then the July issue of Railway Modeller, and then the most recent issue, number 107, of Narrow Gauge and Industrial Railway Modelling REVIEW. The mentions have all been very different but they've allowed me to reflect on whether or not the old adage that there is no such thing as bad publicity is really true or not.

Let's work backwards through time starting with the article in the REVIEW. As you can see from the cover this was a locomotive builders special issue and the editor, Roy C. Link, asked if I could write an article about the Hudson-Hunslet model I built that became the Narrow Planet kit. In a slight departure from other articles I've written this one is essentially a set of photos with extended captions and runs over six pages. It's been beautifully laid out by Roy and I think gives a nice overview of the whole process from initial idea through to the release of the kit. The whole magazine is stuffed full of wonderful modelling (as it always is) and hopefully readers won't think I bring down the tone with my modern 3D printing approach.

Next we have the July issue of Railway Modeller, which included a short item, about a third of a page, on the Lynton and Barnstaple detailing pieces available from Narrow Planet, which includes the chimneys and finials I designed. We had sent the magazine some samples, and while the item was short it was very positive, and probably explains the sudden surge in orders for chimneys I've had to deal with recently.

Which brings us finally to the article in the June issue of British Railway Modelling. The story behind this article goes all the way back to ExpoNG last year when the Hudson-Hunslet kit first went on sale. One of the kits sold on the day (rather than as part of the pre-order) was bough by Ben Jones the editor of British Railway Modelling. I had a really nice chat with Ben and he took a number of photographs of my prototype model (the red one). No promises on an article were made but I made it clear that if he wanted any more information or needed any help with the kit he only had to ask. So when I heard that there was an article on the kit in the June issue I was full of hope. Unfortunately, as I alluded to in a previous post, hope turned to disappointment very very quickly.

Even before I'd managed to get my hands on a copy of the magazine I'd heard rumours that the article was problematic. Unfortunately this proved to be true, but the situation was a lot worse than I feared. In the magazine the article ran over three pages; one page of build photos and captions and then a double page spread mostly taken up with a single large photo and a column of text. Taking a model that is so small and printing a photo across a double page is always going to be rather cruel, but it helps if the model has at least been put together properly. Unfortunately the body and chassis clearly hadn't been fitted together correctly as the axle boxes and axles didn't line up; probably only a mm both vertically and horizontally but when blown up it was glaringly obvious. Plus the locking handles on the bonnet panels hadn't been fitted (even though they were mentioned in the text of the article) leaving odd holes in the model.

The article itself is fairly positive and the build sequence is nice and clear. Unfortunately, Ben admits to having "hit a brick wall" assembling the chassis and having to ask Phil Parker for help, and then states that the supplied figure is "too large for the seat". Yes the driver is a little large but exactly how to make him fit is covered in the instructions, which Ben suggests "reading thoroughly before you start". The issues with the chassis are then covered in a 3 minute video on the accompanying DVD. Essentially once Phil had got it working rather than writing an e-mail he filmed a quick video for Ben never expecting it to be published. Unfortunately it comes across as Phil simply listing things wrong with the kit:

The article raises a wider issue though. Having seen how misleading the article is (in my eyes at least) how can I, or anyone else for that matter, trust any other kit reviews in the magazine? If I'd read the article with no prior knowledge of the kit I'd probably have thought it was badly designed and wouldn't have bought one. Is every other bad kit review I've read similarly misleading? What about good reviews how accurate are they? Of course I'm not talking just about British Railway Modelling here but magazines in general.

I understand from talking this through with some other people that the REVIEW avoids mistakes like this by often running a copy of the article past the kit manufacturer before publication. This probably explains why it's such a well respected magazine. Maybe the main high street magazines should follow suit?

Let's work backwards through time starting with the article in the REVIEW. As you can see from the cover this was a locomotive builders special issue and the editor, Roy C. Link, asked if I could write an article about the Hudson-Hunslet model I built that became the Narrow Planet kit. In a slight departure from other articles I've written this one is essentially a set of photos with extended captions and runs over six pages. It's been beautifully laid out by Roy and I think gives a nice overview of the whole process from initial idea through to the release of the kit. The whole magazine is stuffed full of wonderful modelling (as it always is) and hopefully readers won't think I bring down the tone with my modern 3D printing approach.

Next we have the July issue of Railway Modeller, which included a short item, about a third of a page, on the Lynton and Barnstaple detailing pieces available from Narrow Planet, which includes the chimneys and finials I designed. We had sent the magazine some samples, and while the item was short it was very positive, and probably explains the sudden surge in orders for chimneys I've had to deal with recently.

Which brings us finally to the article in the June issue of British Railway Modelling. The story behind this article goes all the way back to ExpoNG last year when the Hudson-Hunslet kit first went on sale. One of the kits sold on the day (rather than as part of the pre-order) was bough by Ben Jones the editor of British Railway Modelling. I had a really nice chat with Ben and he took a number of photographs of my prototype model (the red one). No promises on an article were made but I made it clear that if he wanted any more information or needed any help with the kit he only had to ask. So when I heard that there was an article on the kit in the June issue I was full of hope. Unfortunately, as I alluded to in a previous post, hope turned to disappointment very very quickly.

Even before I'd managed to get my hands on a copy of the magazine I'd heard rumours that the article was problematic. Unfortunately this proved to be true, but the situation was a lot worse than I feared. In the magazine the article ran over three pages; one page of build photos and captions and then a double page spread mostly taken up with a single large photo and a column of text. Taking a model that is so small and printing a photo across a double page is always going to be rather cruel, but it helps if the model has at least been put together properly. Unfortunately the body and chassis clearly hadn't been fitted together correctly as the axle boxes and axles didn't line up; probably only a mm both vertically and horizontally but when blown up it was glaringly obvious. Plus the locking handles on the bonnet panels hadn't been fitted (even though they were mentioned in the text of the article) leaving odd holes in the model.

The article itself is fairly positive and the build sequence is nice and clear. Unfortunately, Ben admits to having "hit a brick wall" assembling the chassis and having to ask Phil Parker for help, and then states that the supplied figure is "too large for the seat". Yes the driver is a little large but exactly how to make him fit is covered in the instructions, which Ben suggests "reading thoroughly before you start". The issues with the chassis are then covered in a 3 minute video on the accompanying DVD. Essentially once Phil had got it working rather than writing an e-mail he filmed a quick video for Ben never expecting it to be published. Unfortunately it comes across as Phil simply listing things wrong with the kit:

- Mounting pins in the wrong place: no they aren't I'm guessing when Ben added weight to the body he got it in the wrong place so the two halves won't mate properly. An issue highlighted in the instructions and which would explain why the axle boxes and axles don't line up in the photo.

- Replacing the phosphor bronze wire as we only supply a tiny amount: we actually supply three or four times more than necessary so I'm not sure where the extra went.

- That the etched brakes can't be fitted as they would interfere with the pickups: it's clear in the video Phil is trying to fit them to the mounting pins between the wheels not the ones on the corners of the chassis. Again covered clearly in the instructions.

- A general lack of weight: getting weight into such a small model is hard which is why we supply a whitemetal driver figure so it's a shame it wasn't used.

The article raises a wider issue though. Having seen how misleading the article is (in my eyes at least) how can I, or anyone else for that matter, trust any other kit reviews in the magazine? If I'd read the article with no prior knowledge of the kit I'd probably have thought it was badly designed and wouldn't have bought one. Is every other bad kit review I've read similarly misleading? What about good reviews how accurate are they? Of course I'm not talking just about British Railway Modelling here but magazines in general.

I understand from talking this through with some other people that the REVIEW avoids mistakes like this by often running a copy of the article past the kit manufacturer before publication. This probably explains why it's such a well respected magazine. Maybe the main high street magazines should follow suit?

Saturday, July 23, 2016

Whistle While You Work

Unfortunately there hasn't been much time for modelling over the last couple of weeks, but yesterday I decided to find a few minutes to produce another of the small detailing parts for the Skarloey conversion, specifically the whistle. On the prototype the whistle is mounted on top of the dome, but the plastic moulding on the model is very coarse so I decided to replace it with something knocked up from styrene strip, phosphor bronze strip and a turned brass whistle (I already had this in stock, a purchase from 3mm Scale Model Railways when I fitted one to the Quarry Hunslet, so didn't feel the need to turn my own)

There isn't really anything complex or interesting in the modelling here, apart from the way I shaped the styrene strip to be a tight fit into the hole in the casting. I used some 0.8m by 1.5mm strip which is just a little too big in both dimensions for the slot in the casting. Instead of trying to file it down, I simply flooded the hole in the casting with plastic weld, and then gently pushed the strip against the top of the hole. The plastic weld essentially melts the styrene and so I was able to gently work it deeper and deeper into the hole adding a bit more solvent with a brush as needed. Once it was all the way in I left it alone so the plastic would harden then gently pulled it out and trimmed off the flash that had formed. After that it was just a case of fitting the bit of strip metal trimming everything to size and drilling a hole for the whistle to fit.

In the photo all the parts are simply resting in place, which explains the gap between the cab and the casting, this will disappear when everything is properly screwed together. I think the only thing remaining now is to decide if I need any pipework around the dome, otherwise I might be able to move on to painting.

There isn't really anything complex or interesting in the modelling here, apart from the way I shaped the styrene strip to be a tight fit into the hole in the casting. I used some 0.8m by 1.5mm strip which is just a little too big in both dimensions for the slot in the casting. Instead of trying to file it down, I simply flooded the hole in the casting with plastic weld, and then gently pushed the strip against the top of the hole. The plastic weld essentially melts the styrene and so I was able to gently work it deeper and deeper into the hole adding a bit more solvent with a brush as needed. Once it was all the way in I left it alone so the plastic would harden then gently pulled it out and trimmed off the flash that had formed. After that it was just a case of fitting the bit of strip metal trimming everything to size and drilling a hole for the whistle to fit.

In the photo all the parts are simply resting in place, which explains the gap between the cab and the casting, this will disappear when everything is properly screwed together. I think the only thing remaining now is to decide if I need any pipework around the dome, otherwise I might be able to move on to painting.

Saturday, July 2, 2016

Chimney Turning: Take 3

I can't believe it's been over a month since I last wrote a post. I had everything ready to write a new post on another attempt at turning a chimney and then my enthusiasm for modelling suffered a bit of a blow. No I'm not talking about the referendum (although as the result directly affects my job which I might well loose within the next 18 months it didn't help) but some rather public feedback on my modelling. I'm still figuring out if I want to talk about it, but having been away on holiday (which included a railway related day out) I'm feeling a bit better and so on with the story.

Last time I'd managed to turn two chimneys neither of which were usable; one broke and one didn't have the right profile. The third attempt basically followed the same approach as the first two, but once I got to finishing and drilling out the turning I switched from the 3 jaw chuck to using a new purchase; a ER16 collet chuck. The chuck is a genuine EMCO part but the collets themselves are cheap Chinese parts; the entire set cost me less than a single collet often does and they seem accurate enough.

Unfortunately I forgot to take any photos while actually using the collets but, as I said before, the approach was the same as last time, just with a different way of holding the parts. Once I'd turned the chimney (photos of it on it's own appear not to have been taken) I moved on to preparing the body casting by removing the old chimney and drilling a mounting hole.

This involved another new addition to the Unimat 3; a milling table. If you remember, I previously had to hold the casting using the 3 jaw chuck which wasn't particularly stable or safe. I started by extending the existing hole in the chimney down a long way using a drill of roughly the same size to help ensure it was vertical. I then cut the top part off the chimney off with a razor saw and tided up the casting before opening out the hole ready to take the turning.

With the casting prepared it was easy to simply slot the turned chimney into place.

It's not a perfect match for the drawing I have but it's very close (close enough for me at least) to a number of old photos of Tallylyn and more importantly I'm much happier with the turning than the original cast version.

Last time I'd managed to turn two chimneys neither of which were usable; one broke and one didn't have the right profile. The third attempt basically followed the same approach as the first two, but once I got to finishing and drilling out the turning I switched from the 3 jaw chuck to using a new purchase; a ER16 collet chuck. The chuck is a genuine EMCO part but the collets themselves are cheap Chinese parts; the entire set cost me less than a single collet often does and they seem accurate enough.

Unfortunately I forgot to take any photos while actually using the collets but, as I said before, the approach was the same as last time, just with a different way of holding the parts. Once I'd turned the chimney (photos of it on it's own appear not to have been taken) I moved on to preparing the body casting by removing the old chimney and drilling a mounting hole.

This involved another new addition to the Unimat 3; a milling table. If you remember, I previously had to hold the casting using the 3 jaw chuck which wasn't particularly stable or safe. I started by extending the existing hole in the chimney down a long way using a drill of roughly the same size to help ensure it was vertical. I then cut the top part off the chimney off with a razor saw and tided up the casting before opening out the hole ready to take the turning.

With the casting prepared it was easy to simply slot the turned chimney into place.

It's not a perfect match for the drawing I have but it's very close (close enough for me at least) to a number of old photos of Tallylyn and more importantly I'm much happier with the turning than the original cast version.

Wednesday, May 25, 2016

Chimney Turnig

Ever since I first held the model of Skarloey in my hands the chimney has looked wrong. Mostly I think it's that the band around the upper part stands to proud and is too far down. After my success turning buffers and spectacle plates I thought I'd see if I could produce a replacement. Unfortunately thinks didn't go quite to plan this time.

From a drawing of the prototype I worked out all the main measurements and set to work reducing a piece of 6mm diameter brass rod. The first stage was to reduce it down to 4.6mm which is the diameter of the cap, I then reduced most of it down to 3.25mm which is the diameter of the band around the chimney.

I then fitted the top slide to allow me to turn the taper for the cap; I went for a taper of 45 degrees which seemed to match up with the drawing. With the two parts now joined by the taper I cut into the body of the chimney slightly (0.2mm) to produce the top edge of the band, and then turned the rest down by 0.2mm leaving a 1mm wide band. I then worked out where the base of the chimney should be, made a witness mark, and then turned the rest down to 2mm to act as a locating pin.

Next I parted the chimney off from the rest of the bar leaving a few millimetres above the chimney cap, before turning the part around and remounting it with the locating pin in the 3 jaw chuck. I then faced off the top of the cap until I almost met the edge of the taper, I then faced off just the edge leaving a raised section in the middle. The final step was to then drill out the centre of the chimney. I started with a 1.5mm hole but it didn't look big enough so I changed to a 1.8mm drill which is where things started to go wrong.

One of my pet hates on models is chimneys where the central hole is only a millimetre or so deep so I made sure the hole was nice and deep. Unfortunately I forgot that the mounting pin was 2mm wide and my drill was 1.8mm and when it got deep enough the chimney snapped leaving me with the locating pin in the chuck. Worse was to come though when I went to open the chunk only to snap one of the tommy bars.

Fortunately the tommy bar is still useable, if a little short, and in retrospect a number of things were wrong with the chimney. Not only was it too short (I wrongly measured the drawing) but the 45 degree cap looked silly. So I set to turning a second chimney following the same stages which produced something that looks a lot better.

Initially I was happy with this one, but on reflection, and after looking at some photos not just the drawing, it's still not right. I'm happier with the height and the angle of the taper for the cap, but the band is too high up the chimney (there should be more straight section above it before the taper), so I'll have to have another go at some point. I'm still calling it a success though, as it's by far the most complex thing I've turned yet and it's all good practice.

From a drawing of the prototype I worked out all the main measurements and set to work reducing a piece of 6mm diameter brass rod. The first stage was to reduce it down to 4.6mm which is the diameter of the cap, I then reduced most of it down to 3.25mm which is the diameter of the band around the chimney.

I then fitted the top slide to allow me to turn the taper for the cap; I went for a taper of 45 degrees which seemed to match up with the drawing. With the two parts now joined by the taper I cut into the body of the chimney slightly (0.2mm) to produce the top edge of the band, and then turned the rest down by 0.2mm leaving a 1mm wide band. I then worked out where the base of the chimney should be, made a witness mark, and then turned the rest down to 2mm to act as a locating pin.

Next I parted the chimney off from the rest of the bar leaving a few millimetres above the chimney cap, before turning the part around and remounting it with the locating pin in the 3 jaw chuck. I then faced off the top of the cap until I almost met the edge of the taper, I then faced off just the edge leaving a raised section in the middle. The final step was to then drill out the centre of the chimney. I started with a 1.5mm hole but it didn't look big enough so I changed to a 1.8mm drill which is where things started to go wrong.

One of my pet hates on models is chimneys where the central hole is only a millimetre or so deep so I made sure the hole was nice and deep. Unfortunately I forgot that the mounting pin was 2mm wide and my drill was 1.8mm and when it got deep enough the chimney snapped leaving me with the locating pin in the chuck. Worse was to come though when I went to open the chunk only to snap one of the tommy bars.

Fortunately the tommy bar is still useable, if a little short, and in retrospect a number of things were wrong with the chimney. Not only was it too short (I wrongly measured the drawing) but the 45 degree cap looked silly. So I set to turning a second chimney following the same stages which produced something that looks a lot better.

Initially I was happy with this one, but on reflection, and after looking at some photos not just the drawing, it's still not right. I'm happier with the height and the angle of the taper for the cap, but the band is too high up the chimney (there should be more straight section above it before the taper), so I'll have to have another go at some point. I'm still calling it a success though, as it's by far the most complex thing I've turned yet and it's all good practice.

Monday, May 16, 2016

Balance

My work-life balance seems to be all over the place at the moment, and even when I'm at home modelling has ended up fairly low down the list of priorities, but I did find some time this weekend for a little bit of modelling, including a balance pipe!

Due to the chassis block the pipe had to be made in two pieces that put up against the chassis but once it's all painted I think it will do the job. I also added the small pipe from the saddle tank into the drivers side of the cab. This isn't on the prototype now, but is clear on old, pre-preservation photos. No idea what it does but I thought it was worth adding.

Not sure what detail will be next, although I'm still trying to figure out if there is any pipework across the boiler in front of the dome during the early years of the loco. None of the photos I've found are particularly helpful.

Due to the chassis block the pipe had to be made in two pieces that put up against the chassis but once it's all painted I think it will do the job. I also added the small pipe from the saddle tank into the drivers side of the cab. This isn't on the prototype now, but is clear on old, pre-preservation photos. No idea what it does but I thought it was worth adding.

Not sure what detail will be next, although I'm still trying to figure out if there is any pipework across the boiler in front of the dome during the early years of the loco. None of the photos I've found are particularly helpful.

Tuesday, April 12, 2016

More Brass Bits

Yesterday I finally managed to clear enough space (by temporarily dumping things elsewhere) to setup the lathe to turn a full set of spectacle plates. If you remember I ran out of brass after making one last time.

Armed with some new brass rod I set everything up and made a start on turning the 6mm rod down to 4.25mm for the outer diameter. My plan was to turn down quite a length of rod so that I could make four or more in sequence ensuring the outer diameter stayed the same. Initially I must have got the tool height wrong because as soon as I tried to take a small cut the tool dug in which tried to lift the front of the crossslide. While a little bit of pressure on the front of the crossslide stopped that happening the surface finish was terrible. So I stopped, made coffee, and then set everything up again. This time it was fine so I carried on.

The sequence was essentially to turn down the rod for the outer diameter, drill the central hole to 3.5mm (I would possibly have preferred this to be a little bigger but I was limited by drill sizes), face off and then turn down the end to 0.75mm to 4mm in diameter. This leaves me with a frame on the end of the bar which I then parted off. At that point I could just repeat the process from the facing off step to cut more frames.

I decided a photo of just four rings wouldn't be very interesting so instead we have a group shot of the main brass bits I've made for this model.

I actually made six parts, even though I only needed four. The first one I parted off badly which distorted it, and one pinged off never to be seen again during parting off leaving me the four I needed. This does mean that my success rate is climbing since I turned the buffers as two thirds of the parts were usable; it might even have been as high as 80% if I'd been able to find the one that got lost.

There will likely be a bit of a pause again as I'm getting ready for a work meeting next week that won't leave me much, if any, free time but then I have some annual leave so hopefully I'll be able to crack on with the final detailing and some painting...... although that would mean I need to settle on a colour scheme. I'm also not sure yet if I'll fit the window frames before painting, and then paint them brass coloured, or polish them up and fit them after painting. Anyone have any thoughts on which would look best? I'm thinking painting them might help me make them look worn and dirty as I don't want an ex-works condition loco.

Armed with some new brass rod I set everything up and made a start on turning the 6mm rod down to 4.25mm for the outer diameter. My plan was to turn down quite a length of rod so that I could make four or more in sequence ensuring the outer diameter stayed the same. Initially I must have got the tool height wrong because as soon as I tried to take a small cut the tool dug in which tried to lift the front of the crossslide. While a little bit of pressure on the front of the crossslide stopped that happening the surface finish was terrible. So I stopped, made coffee, and then set everything up again. This time it was fine so I carried on.

The sequence was essentially to turn down the rod for the outer diameter, drill the central hole to 3.5mm (I would possibly have preferred this to be a little bigger but I was limited by drill sizes), face off and then turn down the end to 0.75mm to 4mm in diameter. This leaves me with a frame on the end of the bar which I then parted off. At that point I could just repeat the process from the facing off step to cut more frames.

I decided a photo of just four rings wouldn't be very interesting so instead we have a group shot of the main brass bits I've made for this model.

I actually made six parts, even though I only needed four. The first one I parted off badly which distorted it, and one pinged off never to be seen again during parting off leaving me the four I needed. This does mean that my success rate is climbing since I turned the buffers as two thirds of the parts were usable; it might even have been as high as 80% if I'd been able to find the one that got lost.

There will likely be a bit of a pause again as I'm getting ready for a work meeting next week that won't leave me much, if any, free time but then I have some annual leave so hopefully I'll be able to crack on with the final detailing and some painting...... although that would mean I need to settle on a colour scheme. I'm also not sure yet if I'll fit the window frames before painting, and then paint them brass coloured, or polish them up and fit them after painting. Anyone have any thoughts on which would look best? I'm thinking painting them might help me make them look worn and dirty as I don't want an ex-works condition loco.

Labels:

modelling,

OO9,

scratch building,

turning

Sunday, April 10, 2016

The Footplate

So far most of the work on making Skarloey look less like a cartoon character and more like the prototype it is based on, has revolved around detailing above and below the footplate. I have, however, been working for some time on the footplate itself. Specifically I've cut it into two pieces!

As you may remember, I've been working towards a model showing Talyllyn not as it is today but as it was in it's earlier pre-preservation life. So far that had meant moving the blower pipe to the drivers side, but I've now made a more drastic change by altering the footplate. Currently the locomotive has a footplate that runs along both sides of the boiler and encloses the tops of the wheels. Originally though there was no such footplate, with just a thin strip on the fireman’s side to give him somewhere to stand when topping up the water tank. To model this I've cut away the plastic footplate and added a thin metal strip which results in this.

It still needs some tidying up and a little filler in places but I think that looks fairly promising. You also notice that I've remove the box (I assume toolboxes although could be a sandbox I suppose) from the front right as again originally there was only one on the front left.

I think the main things left now are the remaining window frames and possibly a replacement chimney, but both require me fully reclaiming my desk again so I can get the lathe out. Hopefully that won't take too much longer.

As you may remember, I've been working towards a model showing Talyllyn not as it is today but as it was in it's earlier pre-preservation life. So far that had meant moving the blower pipe to the drivers side, but I've now made a more drastic change by altering the footplate. Currently the locomotive has a footplate that runs along both sides of the boiler and encloses the tops of the wheels. Originally though there was no such footplate, with just a thin strip on the fireman’s side to give him somewhere to stand when topping up the water tank. To model this I've cut away the plastic footplate and added a thin metal strip which results in this.

It still needs some tidying up and a little filler in places but I think that looks fairly promising. You also notice that I've remove the box (I assume toolboxes although could be a sandbox I suppose) from the front right as again originally there was only one on the front left.

I think the main things left now are the remaining window frames and possibly a replacement chimney, but both require me fully reclaiming my desk again so I can get the lathe out. Hopefully that won't take too much longer.

Saturday, March 26, 2016

A Little Less Like a Cartoon Character

I hate having to pack away my modelling stuff when people come to stay as I never end up getting the space back quickly. This time it's been over a month since I last had anything to report, and in fact I've still not cleared my workbench. Mostly this is because work has been hectic, but we've also been trying to tidy the house a bit so keeping stuff on my desk has given us more room to work. Anyway, this morning I managed to grab a little time and space to do some more work on turning the model of Skarloey into less of a cartoon character.

As well as the face, the main problem with the model, as it comes, is that the cylinders are seriously over sized compared with the loco on which Skarloey is based. Also, probably as it's marketed as a toy, the crossheads are seriously chunky looking. Fortunately all these problems can be solved with Narrow Planet's new detailing kit. This kit is truly a joint effort containing parts from four different people, which improve the look of different aspects of the model. I won't necessarily be using all the bits in the kit but I've now fitted the new cylinders, slidebars, connecting rods, coupling rods, and crossheads.

It's once you get the original cylinders off the model when it becomes obvious just how big they are, or how small the replacements are in comparison. The new cylinders just slide onto the chassis, but the slidebar brackets and crossheads need soldering together before they can be fitted. Fortunately the etch design makes this really easy as you just align the outer frames using some cocktail sticks and then let solder wick between the layers. One thing you have to be careful with is that originally the brackets for the slidebars were plastic so it's important to make sure the metal replacements don't cause a short; hence why I've painted them and nothing else.

Fitting all the parts is very straight forward and the model is soon back running again. I made slightly more work for myself as in stripping the model right down (something you don't need to do if you are just fitting the detailing kit), I managed to have almost all the motor wires come loose -- the original soldering to the small board was shockingly bad. Anyway now I have the new cylinders and slidebar brackets in place I can start to build the rest of the bodywork back up.

As well as the face, the main problem with the model, as it comes, is that the cylinders are seriously over sized compared with the loco on which Skarloey is based. Also, probably as it's marketed as a toy, the crossheads are seriously chunky looking. Fortunately all these problems can be solved with Narrow Planet's new detailing kit. This kit is truly a joint effort containing parts from four different people, which improve the look of different aspects of the model. I won't necessarily be using all the bits in the kit but I've now fitted the new cylinders, slidebars, connecting rods, coupling rods, and crossheads.

It's once you get the original cylinders off the model when it becomes obvious just how big they are, or how small the replacements are in comparison. The new cylinders just slide onto the chassis, but the slidebar brackets and crossheads need soldering together before they can be fitted. Fortunately the etch design makes this really easy as you just align the outer frames using some cocktail sticks and then let solder wick between the layers. One thing you have to be careful with is that originally the brackets for the slidebars were plastic so it's important to make sure the metal replacements don't cause a short; hence why I've painted them and nothing else.

Fitting all the parts is very straight forward and the model is soon back running again. I made slightly more work for myself as in stripping the model right down (something you don't need to do if you are just fitting the detailing kit), I managed to have almost all the motor wires come loose -- the original soldering to the small board was shockingly bad. Anyway now I have the new cylinders and slidebar brackets in place I can start to build the rest of the bodywork back up.

Labels:

modelling,

Narrow Planet,

OO9

Monday, February 29, 2016

Monocle

When working on the cab yesterday I realised that the rear windows didn't have any moulded surrounds. The front windows do have surrounds and I'd been intending to leave them as they didn't look too bad. As even old photos show rims around the rear windows I'm going to need to do something about them, so I think I'll now be replacing the ones on the front as well. On every model I've fitted window rims to they have been etched and while I could easily go that route I thought I'd see if I could turn them instead. Unfortunately after making the buffers I had just a tiny piece of rod that was roughly the right size left so as a test I made a monocle instead of a spectacle.

The hole in the cab is approximately 3.5mm so I opened this out to 4mm and then turned a rim with an outer diameter of 4.25mm and a central hole 3.5mm across that was a push fit in the enlarged hole. It probably needs for the rim to be slightly less proud of the cab and the edge rounded if possible, but as a first test this shows that the approach should work (a good job after I'd opened out one window hole already) so when the 6mm brass rod I have on order arrives I'll turn four rims rather than drawing up etch artwork.

The hole in the cab is approximately 3.5mm so I opened this out to 4mm and then turned a rim with an outer diameter of 4.25mm and a central hole 3.5mm across that was a push fit in the enlarged hole. It probably needs for the rim to be slightly less proud of the cab and the edge rounded if possible, but as a first test this shows that the approach should work (a good job after I'd opened out one window hole already) so when the 6mm brass rod I have on order arrives I'll turn four rims rather than drawing up etch artwork.

Sunday, February 28, 2016

Replacing Moulded Details

One of the things that now often puts me off buying ready to run models is the inclusion of moulded details. While I understand that fitting details by hand to a model would raise the price above what was economically viable, I think they nearly always ruin the look of what may otherwise be a fine model. On Skarloey there are lots of moulded details; in fact I don't think there is a single detail which isn't moulded. Given I don't have to worry about damaging the paint finish etc. I've decided to really go to town and replace many if not all of the moulded details.

So far I've removed the following details from the model; rear lamp, rear lamp brackets, blower pipe, cab handrails, drivers side boiler handrail, the number plate on the cab rear, and a small disc like feature from the cab rear the function of which I'm at a loss to explain.

Of those details so far I've only replaced the blower pipe and cab handrails but already I think that dramatically improves the model. Interestingly I didn't just have to replace the blower pipe but I've moved it from the firemans side (where it is currently on the prototype) to the drivers side where it was pre-preservation. This also raises the issue of which of the other details I need to add back. For example, the only old photo I've found showing the rear of the cab doesn't show any lamp brackets or a number plate, although a drawing I have shows one lamp bracket rather than the three currently fitted. I'll keep looking for more photos before I make any decisions but if anyone knows when the extra brackets etc. were added or any other info about such small details it would be great if you could leave a comment.

So far I've removed the following details from the model; rear lamp, rear lamp brackets, blower pipe, cab handrails, drivers side boiler handrail, the number plate on the cab rear, and a small disc like feature from the cab rear the function of which I'm at a loss to explain.

Of those details so far I've only replaced the blower pipe and cab handrails but already I think that dramatically improves the model. Interestingly I didn't just have to replace the blower pipe but I've moved it from the firemans side (where it is currently on the prototype) to the drivers side where it was pre-preservation. This also raises the issue of which of the other details I need to add back. For example, the only old photo I've found showing the rear of the cab doesn't show any lamp brackets or a number plate, although a drawing I have shows one lamp bracket rather than the three currently fitted. I'll keep looking for more photos before I make any decisions but if anyone knows when the extra brackets etc. were added or any other info about such small details it would be great if you could leave a comment.

Wednesday, February 24, 2016

Success Rate: 40%

The feedback on my first attempt at turning a buffer suggested that the problems with the surface finish were related to the speed at which they were being made. Specifically that I was probably turning the lead screw too quickly, but also that I might need to run the lathe faster than the 1500rpm I was using. I've now had another go using a faster lathe speed of 2450rpm while turning the lead screw much more slowly. This reduced the problem considerably although I notieced that the grooving was still present but was only happening when reversing the lead screw so was solvable by backing off the crossslide after taking the last cut to set a specific diameter. After a few false starts, mostly related to me not being able to count, I've now produced four almost identical buffers that I'm more than happy with.

In total I've turned 10 buffers giving me a success rate of just 40% but for my first lathe based project I don't think that's too bad at all. One thing I did learn is that I really want some resettable handwheels. In the end I resorted to facing off the brass bar until the dial read 0 so that it was easy to count out the other measurements along the bar. I also know I really want a collet chuck for holding small items as doing the final work with the buffer held in the 3 jaw chuck by the locating pin was fraught with problems and in one case I ended up with it clamped out of centre somehow which ruined the buffer when I added an off centre notch around the front face.

Anyway, I'm really happy with how these have turned out and in retrospect I'm actually quite impressed that the success rate is as high as 40%, I thought I'd go through a lot more brass than that before producing four usable buffers!

In total I've turned 10 buffers giving me a success rate of just 40% but for my first lathe based project I don't think that's too bad at all. One thing I did learn is that I really want some resettable handwheels. In the end I resorted to facing off the brass bar until the dial read 0 so that it was easy to count out the other measurements along the bar. I also know I really want a collet chuck for holding small items as doing the final work with the buffer held in the 3 jaw chuck by the locating pin was fraught with problems and in one case I ended up with it clamped out of centre somehow which ruined the buffer when I added an off centre notch around the front face.

Anyway, I'm really happy with how these have turned out and in retrospect I'm actually quite impressed that the success rate is as high as 40%, I thought I'd go through a lot more brass than that before producing four usable buffers!

Tuesday, February 23, 2016

Third Turn's a Charm (Almost)

Having finished the boiler backhead and cab detailing (or at least the bits attached to the body casting) I've turned my attention to one of the other details of the original model which I think can be improved... the buffers. Certainly the loco is currently fitted with some rather distinctive buffers that have a circular core wrapped with a metal band as you can see in this photo.

If you remember back to the original model the buffer heads are just plain disks. Now no matter how skilled I might be with a file there is no way I could accurately file those heads down to represent the prototype and anyway given I own a lathe turning replacements sounds like a lot more fun.

I've actually been thinking about how to turn replacements for a few days, as having never turned anything without Paul's supervision I had to think about the best way of approaching them all on my own. In the end I drew a picture with dimensions and then a list of steps (on the left hand side, the right hand side is notes I made while turning the first attempt).

If you can't read my handwriting (sometimes I can't even read it so I wouldn't be surprised if most of you think it illegible) by plan was to basically work inwards in steps; turn the bar down to the max width of the head first, then turn down the rest to the width of the shank, and then turn down just the locating pin. The only complications being the slightly smaller diameter of the front and back of the buffer head. Turning the one on the back of the buffer head is easy, but the one on the front I decided probably needed doing after I'd parted off the buffer by turning the buffer around and mounting it on the lathe using the locating pin. After lots of careful measuring and turning I had my first attempt completed.

Unfortunately, just as with my first turning, I managed to loose some of the buffer head when parting off, so the head ended up being a lot thinner than I intended, so much so I didn't bother to re-mount it to do the final work on the front face. While it was far from perfect I had at least turned something so I set off to have another go. This time I managed to make the buffer head too big when parting off and when I went to try and rectify this with it mounted the other way around in the lathe, I got my handles mixed up and took off too much, so that was also a bust. On the third attempt though (I still parted off too much but I then faced off the buffer to thin it down) I produced something that dimensionally I was fairly happy with.

The shank could do with being a touch thinner but I could live with it as it is now. The main problem is that the surface is not very smooth. I'm guessing I've not set something up right as I basically end up with lots of grooves around the turning, which are easy to see in the photo and easy to feel as well. After my experience last time I made sure everything was nice and tight and as far as I can tell nothing shifted while in use. My guess is I've got the tool at the wrong height or angle, but I'm not entirely sure. Anyone have any suggestions as I need to figure out what I'm doing wrong before it's worth turning a full set of four replacement buffers.

If you remember back to the original model the buffer heads are just plain disks. Now no matter how skilled I might be with a file there is no way I could accurately file those heads down to represent the prototype and anyway given I own a lathe turning replacements sounds like a lot more fun.

I've actually been thinking about how to turn replacements for a few days, as having never turned anything without Paul's supervision I had to think about the best way of approaching them all on my own. In the end I drew a picture with dimensions and then a list of steps (on the left hand side, the right hand side is notes I made while turning the first attempt).

If you can't read my handwriting (sometimes I can't even read it so I wouldn't be surprised if most of you think it illegible) by plan was to basically work inwards in steps; turn the bar down to the max width of the head first, then turn down the rest to the width of the shank, and then turn down just the locating pin. The only complications being the slightly smaller diameter of the front and back of the buffer head. Turning the one on the back of the buffer head is easy, but the one on the front I decided probably needed doing after I'd parted off the buffer by turning the buffer around and mounting it on the lathe using the locating pin. After lots of careful measuring and turning I had my first attempt completed.

Unfortunately, just as with my first turning, I managed to loose some of the buffer head when parting off, so the head ended up being a lot thinner than I intended, so much so I didn't bother to re-mount it to do the final work on the front face. While it was far from perfect I had at least turned something so I set off to have another go. This time I managed to make the buffer head too big when parting off and when I went to try and rectify this with it mounted the other way around in the lathe, I got my handles mixed up and took off too much, so that was also a bust. On the third attempt though (I still parted off too much but I then faced off the buffer to thin it down) I produced something that dimensionally I was fairly happy with.

The shank could do with being a touch thinner but I could live with it as it is now. The main problem is that the surface is not very smooth. I'm guessing I've not set something up right as I basically end up with lots of grooves around the turning, which are easy to see in the photo and easy to feel as well. After my experience last time I made sure everything was nice and tight and as far as I can tell nothing shifted while in use. My guess is I've got the tool at the wrong height or angle, but I'm not entirely sure. Anyone have any suggestions as I need to figure out what I'm doing wrong before it's worth turning a full set of four replacement buffers.

Monday, February 22, 2016

The Big Wheel

Today I've spent a little time adding two more details to the cab interior, specifically that big wheel (I'm assuming it's the brake), and the pipework that runs across and down the sides of the backhead. Unfortunately I didn't have any spare wheels of the right type or size so I had to knock one up from some brass wire. The pipework was at least nice and easy as I did have some small etched handwheels (on the same sheet from RT Models as the reversing lever) and the rest was just wire.

Again not necessarily an accurate rendition but they will do the job nicely. I may need to add a few more details but these will be fixed inside the upper plastic part of the cab so I think this finishes the backhead parts attached to the body casting.

Again not necessarily an accurate rendition but they will do the job nicely. I may need to add a few more details but these will be fixed inside the upper plastic part of the cab so I think this finishes the backhead parts attached to the body casting.

Sunday, February 21, 2016

Making the Right Impression

So having added the firebox door yesterday, today I added the regulator handle and the two gauge glasses. In the process I managed to remove the firebox door and the boiler wrapper, so the entire backhead has now been rebuilt.

It's not quite as neat as it was before and the lesson is that I need to buy some low melt solder for adding details without unsoldering the main parts. While it may not be pretty I'm still happy with it as it is still performing the job I'm building it for... to give an impression of a cab interior when glimpsed through the door.

I don't know about you but I think that does the job adequately enough.

It's not quite as neat as it was before and the lesson is that I need to buy some low melt solder for adding details without unsoldering the main parts. While it may not be pretty I'm still happy with it as it is still performing the job I'm building it for... to give an impression of a cab interior when glimpsed through the door.

I don't know about you but I think that does the job adequately enough.

Saturday, February 20, 2016

Fuel Goes In Here

So having fitted a very basic cab interior to the main body casting of Skorloey (which I really should start referring to as TR No.1) I've made a start on adding some more details to the boiler backhead. The first item to be added was the firebox door, and it's probably going to take me longer to write this post than it did to make the thing.

I made a very basic template on the computer to give me the right sized oval with two pieces of strapping. This was printed out, stuck to a sheet of 0.12mm brass and then cut out and filed to shape. The point of a small round file was then used to gently punch some rivets into the strapping. The only other item required was a bit of 0.45mm brass wire to act as the hinge. Assembly then simply involved smearing some solder paste on the rear of the strapping and then folding the strapping around the wire and over the door. A quick touch from a soldering iron and everything was fixed solid and could be tided up.

The finished door then had some more solder paste smeared on the back, it was positioned on the backhead and another brief use of the soldering iron fixed it in place. A quick clean up with a file and fibreglass pen and the job was done. As with the rest of the cab details it might not hold up well under close scrutiny but when glimpsed through the door of the cab past he legs of the driver or fireman it should give the right impression.

I made a very basic template on the computer to give me the right sized oval with two pieces of strapping. This was printed out, stuck to a sheet of 0.12mm brass and then cut out and filed to shape. The point of a small round file was then used to gently punch some rivets into the strapping. The only other item required was a bit of 0.45mm brass wire to act as the hinge. Assembly then simply involved smearing some solder paste on the rear of the strapping and then folding the strapping around the wire and over the door. A quick touch from a soldering iron and everything was fixed solid and could be tided up.

The finished door then had some more solder paste smeared on the back, it was positioned on the backhead and another brief use of the soldering iron fixed it in place. A quick clean up with a file and fibreglass pen and the job was done. As with the rest of the cab details it might not hold up well under close scrutiny but when glimpsed through the door of the cab past he legs of the driver or fireman it should give the right impression.

Friday, February 19, 2016

Inner Space

Having removed the coal from the top of the drivers side bunker I decided I'd continue working on the main body casting by doing something about the inside of the cab. On the unaltered "toy" the cab contains a full height plate with no details at all. I'm guessing this was added to give extra strength to the plastic cab but not only does it look wrong when you look through the cab doors but you can't even look through the windows. Removing the top half of the plate was the first thing I did to the casting, even before I took photos of the parts or stripped them of paint. Originally i thought that was all I would do but having thought about it some more I decided to go further and hack out more of the plate so I could fit some details within the cab.

For an idea of what I aiming for here is a useful photo of the prototype without it's cab allowing a good view of the boiler backhead.

The first stage was to cut away more of the vertical plate to allow space either side of the boiler for the coal bunker door and the reversing lever on either side. As I found before the casting is actually quite solid so this took some time. On both sides I cut two vertical slots with a razor saw and then used pliers to snap the piece of the casting away, before tidying up (to a certain extent) with small files.

With space on either side of the boiler I then set about making pieces to fill the gaps. Working with 0.12mm brass sheet I made two parts that fitted nicely either side. These parts were then detailed. On the left side I added a representation of a door into the coal bunker, while on the right I added a reversing lever. The reversing lever was made by cutting down on on an etch of detailing parts from RT Models and making up the base from more brass sheet. The two parts were then glued onto the casting (I did try soldering but the casting just soaks up the heat and I didn't fancy using the blowtorch on the small details).

The next stage was the boiler backhead itself. It ook me four attempts to get something I was happy with. My first couple of attempts involved trying to cut out the right shape and then gluing bits of styrene to the back to hold it in the right place over the casting and then filing the styrene to give the round shape of the boiler. After what seemed like hours with no end in sight I gave up. The next couple, including the final result, were made by roughly rolling a piece of brass sheet to the right diameter, soldering that to a flat sheet and then cutting and filling to give something that would slot over the casting.

Getting the initial shape right was actually quite easy, and then it was just a case of filing and testing it on the casting over and over until I was happy with the result.

It's not a perfect representation of the real thing but once the cab is in place I think even in it's current state it will do the job of providing some detail to glimpse through the door. I am, however, not yet finished as I'm intending to add some of the pipework, a firebox door and that large wheel is a must.

For an idea of what I aiming for here is a useful photo of the prototype without it's cab allowing a good view of the boiler backhead.

The first stage was to cut away more of the vertical plate to allow space either side of the boiler for the coal bunker door and the reversing lever on either side. As I found before the casting is actually quite solid so this took some time. On both sides I cut two vertical slots with a razor saw and then used pliers to snap the piece of the casting away, before tidying up (to a certain extent) with small files.

With space on either side of the boiler I then set about making pieces to fill the gaps. Working with 0.12mm brass sheet I made two parts that fitted nicely either side. These parts were then detailed. On the left side I added a representation of a door into the coal bunker, while on the right I added a reversing lever. The reversing lever was made by cutting down on on an etch of detailing parts from RT Models and making up the base from more brass sheet. The two parts were then glued onto the casting (I did try soldering but the casting just soaks up the heat and I didn't fancy using the blowtorch on the small details).

The next stage was the boiler backhead itself. It ook me four attempts to get something I was happy with. My first couple of attempts involved trying to cut out the right shape and then gluing bits of styrene to the back to hold it in the right place over the casting and then filing the styrene to give the round shape of the boiler. After what seemed like hours with no end in sight I gave up. The next couple, including the final result, were made by roughly rolling a piece of brass sheet to the right diameter, soldering that to a flat sheet and then cutting and filling to give something that would slot over the casting.

Getting the initial shape right was actually quite easy, and then it was just a case of filing and testing it on the casting over and over until I was happy with the result.

It's not a perfect representation of the real thing but once the cab is in place I think even in it's current state it will do the job of providing some detail to glimpse through the door. I am, however, not yet finished as I'm intending to add some of the pipework, a firebox door and that large wheel is a must.

Subscribe to:

Posts (Atom)