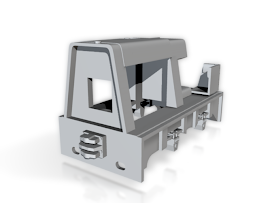

After all the positive comments on the Hunslet axlebox I've pushed on with the rest of the model I've been working on. Given that I'm now planning a layout based around the test track at the Robert Hudson Ltd factory I decided I needed an appropriate locomotive. Hudson's didn't manufacture locomotives themselves but instead entered into partnerships with other firms to sell branded locomotives. One of these partnerships was with the Hunslet Engine Company and I decided to have a go at modelling one of their tiny 24HP diesel locomotives. These were produced for a number of different narrow gauges and in a variety of cab configurations. My current model is based around a cabless 2' 6" gauge version.

If you are at all familiar with the prototype then you'll notice that quite a few bits of body work are missing. The plan is to add these using etched brass parts which I have yet to draw up. In fact I'm hoping to use the model with different etched parts to produce different versions with different cabs.

This is by far the most complex model I've ever attempted to build. Not only is the 3D printed part quite complex, there will be the etched parts, and I'm intending to build the chassis as well as I was unable to find one with the right wheel base; you may remember I've already bought some parts for this. I've no idea if this will work or not as there are so many parts I'll need to get just right, but if I do manage to pull it off then, depending how complex it is to assemble, it might become a Narrow Planet kit, assuming there is enough interest.

Tuesday, December 30, 2014

Monday, December 29, 2014

Christmas Modelling

I hope you've all had a great Christmas and are looking forward to 2015. I'd planned on doing some more 3D modelling over the holiday (I wasn't spending it at home and my modelling stuff has all been packed away for the holidays), but this is the sum total of the modelling I achieved; a Hunslet axlebox.

Of course a lack of modelling just means I had a great Christmas with lots to do and friends to see. Unfortunately I'm back at work this week, so I'm not likely to get much more modelling done, but when I do at least I'll have an axlebox around which to build a model!

Of course a lack of modelling just means I had a great Christmas with lots to do and friends to see. Unfortunately I'm back at work this week, so I'm not likely to get much more modelling done, but when I do at least I'll have an axlebox around which to build a model!

Friday, December 19, 2014

Chimney Pots and Finials

The Lynton and Barnstaple Railway has a long history, and efforts are now underway to rebuild substantial portions of the line. In parallel to this real world expansion a number of model railway companies have started to produce models related to the railway, specifically the station at Woody Bay. For example, here is a photo of the station as well as a photo of the model produced by Bachmann.

Now while the model is exceptionally detailed there are a couple of things that are missing or not quite right. Most obviously the chimney pots are wrong. The real chimneys are quite ornate and very distinctive, yet the model has very plain chimney pots. Also the roof sports ornate finials which are entirely missing from the model. I'm guessing both these changes were made as the details would be too fine to mass produce and would have had to be hand fitted increasing the cost of the models.

Given that I'm not modelling the Lynton and Barnstaple railway I hadn't actually noticed the problem as I'd not looked closely at the models. The members of the Lynton and Barnstaple Modelling Yahoo! Group had noticed though and they asked Narrow Planet if they would be willing to produce 3D printed chimney pots and finials to complement the building models. At this point you may be asking how I know this? The answer is that I'm the newest Narrow Planet designer, and the chimney pots and finials are the first products I've designed to be released.

Working from scale drawings and plenty of photos I was able to produce a 3D model of both the chimney pots and the finials, and I've now received the first test prints. I find photographing raw FUD prints difficult as all the detail tends to disappear so I painted one chimney to help show the detail (RailMatch freight Bauxite followed by a thin black wash).

Personally I think these have turned out really nicely and as there was no problem with the test prints they are now available to buy. They aren't listed yet on the Narrow Planet website, but you can order them via e-mail. A sprue of 10 chimneys will set you back £6, while a sprue of 10 finials will cost you £3; both those prices include UK P&P. Hopefully the odd chimney pots will appeal to a wide range of modellers who might be looking for something a little different as well as those modelling the Lynton and Barnstaple Railway.

For those wondering what this means for Penistone Railway Works my answer is that for now you won't see any difference. All the models that are currently available will remain so, and there may be new models in the future that don't fit well with Narrow Planet. What it does mean though is that I can now contemplate models which would only be possible using multiple materials rather than just single printed items sold via Shapeways. Hopefully this will mean more models for everyone to enjoy.

Now while the model is exceptionally detailed there are a couple of things that are missing or not quite right. Most obviously the chimney pots are wrong. The real chimneys are quite ornate and very distinctive, yet the model has very plain chimney pots. Also the roof sports ornate finials which are entirely missing from the model. I'm guessing both these changes were made as the details would be too fine to mass produce and would have had to be hand fitted increasing the cost of the models.

Given that I'm not modelling the Lynton and Barnstaple railway I hadn't actually noticed the problem as I'd not looked closely at the models. The members of the Lynton and Barnstaple Modelling Yahoo! Group had noticed though and they asked Narrow Planet if they would be willing to produce 3D printed chimney pots and finials to complement the building models. At this point you may be asking how I know this? The answer is that I'm the newest Narrow Planet designer, and the chimney pots and finials are the first products I've designed to be released.

Working from scale drawings and plenty of photos I was able to produce a 3D model of both the chimney pots and the finials, and I've now received the first test prints. I find photographing raw FUD prints difficult as all the detail tends to disappear so I painted one chimney to help show the detail (RailMatch freight Bauxite followed by a thin black wash).

Personally I think these have turned out really nicely and as there was no problem with the test prints they are now available to buy. They aren't listed yet on the Narrow Planet website, but you can order them via e-mail. A sprue of 10 chimneys will set you back £6, while a sprue of 10 finials will cost you £3; both those prices include UK P&P. Hopefully the odd chimney pots will appeal to a wide range of modellers who might be looking for something a little different as well as those modelling the Lynton and Barnstaple Railway.

For those wondering what this means for Penistone Railway Works my answer is that for now you won't see any difference. All the models that are currently available will remain so, and there may be new models in the future that don't fit well with Narrow Planet. What it does mean though is that I can now contemplate models which would only be possible using multiple materials rather than just single printed items sold via Shapeways. Hopefully this will mean more models for everyone to enjoy.

Wednesday, December 10, 2014

Pac-Man

While I'd never normally advocate adding graffiti to anything, this addition to the damaged paintwork on the Northern Rail train I took to work on Monday really did make me smile.

Saturday, December 6, 2014

Hudson's Pizza

So the time has finally come to unveil the plan for my next layout. Given that I'm still not happy with the track plan for 77 Box Lane that will stay on the drawing board for now, and this is an entirely new and different layout.

One of the things I liked about my N gauge layout, Jerusalem (which is now boxed up and being stored in the loft) was that it had a roundy-roundy track plan so I could just watch the trains go by. It was also useful for running in and testing new locomotives as they could be left going for hours if necessary without any intervention. Given the size I had to play with 77 Box Lane was always going to be an end-to-end layout and while I'm happy with that (although not the current track plan) I did feel it would be useful to have some form of continuous run test track, even if that was a simple circle of temporary track.

I wasn't actively planning a new layout when a random comment sent me off on a bit of historical research. I grew up in Morley, a small town just outside Leeds, and I've known for a long time (pretty much as long as I can remember) that many of the early builders of locomotives and rolling stock were based in and around Leeds; it's one of the reasons I have a soft spot for the Quarry Hunslet locomotives. What I didn't know, until recently, was that I actually grew up less than three miles from the main works of one of the companies.

Robert Hudson Ltd was founded in 1865 and had it's main works at Gildersome a small village just outside Morley (it's officially been part of Morley since 1937). This was a huge site covering 38 acres and was well served by a 2 foot tramway. Raw materials and finished products arrived and left the site via the standard gauge branch line that formed the northern edge of the site. You can see these and many other details on both the 1938 map and a 1928 aerial photograph.

What immediately caught my eye though was the circular feature which is very clear on the map, but unfortunately is unlabelled as to purpose. Zooming in on the photo though and it's purpose becomes clearer. It's a circular test track on which you can see what looks like a couple of wagons.

To me this looks perfect for turning into a pizza layout. It will give me somewhere to test and run in locomotives and wagons while being based on an actual location. There also appears to be a variety of building styles to perfect and some dry stone walling. I know that so far I've not built any Hudson wagons or locomotives which they re-sold (they didn't build their own but rather re-sold those produced by companies such as Hudswell Clarke, Kerr Stuart, and Hunslet) but I can always apply Rule 1 of railway modelling; it's my trainset so I'll run whatever I want to!

The problem I have is that this grainy photo contains the only details I have on the buildings surrounding the test track. There is a drawing in Alan J. Haigh's book on the foundry (published by the Moseley Railway Trust) but it doesn't provide any extra details. So does anyone know of any further drawings or photos of that area of the works that might show more details of the buildings. If you do please leave a comment.

From some rough measurements, I believe that I can fit the circle of track and the buildings immediately surrounding it onto a board that will fit into the box I originally bought for Jerusalem but which was about 1cm too small. So this means it will fit on my desk and I'll have storage for it. The next step will be a full scale mockup (starting from the map) to check everything will fit and then I can make a start on the baseboard and then building some track. This should be fun!

One of the things I liked about my N gauge layout, Jerusalem (which is now boxed up and being stored in the loft) was that it had a roundy-roundy track plan so I could just watch the trains go by. It was also useful for running in and testing new locomotives as they could be left going for hours if necessary without any intervention. Given the size I had to play with 77 Box Lane was always going to be an end-to-end layout and while I'm happy with that (although not the current track plan) I did feel it would be useful to have some form of continuous run test track, even if that was a simple circle of temporary track.

I wasn't actively planning a new layout when a random comment sent me off on a bit of historical research. I grew up in Morley, a small town just outside Leeds, and I've known for a long time (pretty much as long as I can remember) that many of the early builders of locomotives and rolling stock were based in and around Leeds; it's one of the reasons I have a soft spot for the Quarry Hunslet locomotives. What I didn't know, until recently, was that I actually grew up less than three miles from the main works of one of the companies.

Robert Hudson Ltd was founded in 1865 and had it's main works at Gildersome a small village just outside Morley (it's officially been part of Morley since 1937). This was a huge site covering 38 acres and was well served by a 2 foot tramway. Raw materials and finished products arrived and left the site via the standard gauge branch line that formed the northern edge of the site. You can see these and many other details on both the 1938 map and a 1928 aerial photograph.

What immediately caught my eye though was the circular feature which is very clear on the map, but unfortunately is unlabelled as to purpose. Zooming in on the photo though and it's purpose becomes clearer. It's a circular test track on which you can see what looks like a couple of wagons.

To me this looks perfect for turning into a pizza layout. It will give me somewhere to test and run in locomotives and wagons while being based on an actual location. There also appears to be a variety of building styles to perfect and some dry stone walling. I know that so far I've not built any Hudson wagons or locomotives which they re-sold (they didn't build their own but rather re-sold those produced by companies such as Hudswell Clarke, Kerr Stuart, and Hunslet) but I can always apply Rule 1 of railway modelling; it's my trainset so I'll run whatever I want to!

The problem I have is that this grainy photo contains the only details I have on the buildings surrounding the test track. There is a drawing in Alan J. Haigh's book on the foundry (published by the Moseley Railway Trust) but it doesn't provide any extra details. So does anyone know of any further drawings or photos of that area of the works that might show more details of the buildings. If you do please leave a comment.

From some rough measurements, I believe that I can fit the circle of track and the buildings immediately surrounding it onto a board that will fit into the box I originally bought for Jerusalem but which was about 1cm too small. So this means it will fit on my desk and I'll have storage for it. The next step will be a full scale mockup (starting from the map) to check everything will fit and then I can make a start on the baseboard and then building some track. This should be fun!

Thursday, December 4, 2014

A Crazy Idea?

I've recently come across drawings for a loco I fancy building. Strangely, for me at least, it's a small 0-4-0 diesel engine rather; the identify of which will, for now at least, remain a mystery. The problem is that with a wheel base of just 2 foot 10 inches I've been unable to find a suitable ready-to-run chassis. Not only did every chassis I could find have a larger wheelbase but I also want the gap between the wheels to be empty and most of them have a solid chassis block. So the crazy idea... I'm going to have a go at building my own chassis for it.

I've no idea if I'll be able to pull off building a chassis from scratch but as you can see I've made a start by buying a bunch of components from Nigel Lawton. This pile includes a motor, pulleys, belts, gears, wheels, and various other items. My plan is to 3D print the basic chassis block and then to add these parts to it. I've got the first prototype chassis on order, although I think it will need a couple of revisions before I get it right, but it should be fun.

I've no idea if I'll be able to pull off building a chassis from scratch but as you can see I've made a start by buying a bunch of components from Nigel Lawton. This pile includes a motor, pulleys, belts, gears, wheels, and various other items. My plan is to 3D print the basic chassis block and then to add these parts to it. I've got the first prototype chassis on order, although I think it will need a couple of revisions before I get it right, but it should be fun.

Monday, December 1, 2014

How to Electrify a Frog

Some of you may remember that since May I've been slowly documenting my attempts at point control (here, here, and here). All the posts so far have dealt with the mechanical side of changing the points and have completely ignored what happens to the power running through the rails.

In theory the PECO points can be used straight from the packet, but from prior experience I won't be doing that ever again. The problem is that, as manufactured, the points rely on the contact between the switch and stock rails to provide power. While this works well with a new point as soon as you try and paint, weather, or ballast the track it is exceedingly likely that the point of contact will be obscured and the power flow will either stop entirely or be very temperamental. On Jerusalem, I had no end of problems with the one scenic point and no amount of careful cleaning would give me a reliable point. The solution to this is to perform a small amount of surgery on the point so that we no longer rely on the contact between the rails to transfer the power.

Before we start altering the point we need to ensure some consistent terminology so that the instructions are clear. So here we have an annotated photo of a right hand PECO crazy track OO9 point.

Now that we are all on the same page here are four simple steps to upgrade the point.

Step 1

Counting from the vee end of the point, use a small razor saw to remove the webbing from under the inner vee rails between the first and second sleepers and also the webbing from under all four rails between sleepers six and seven (helpfully these are the sleepers with writing on the bottom). Be careful not to cut into the rails and try and make sure the sleepers don't slide along the rails.

Step 2

Add a small amount of superglue (the runny kind not a gel) at each point indicated in the photo. Capillary action will help draw the glue into the gap between the rails and sleepers and will help to hold the point together. Once the glue has dried use a small file or fibreglass pen to clean the newly exposed rail surfaces.

Step 3

Solder three wires to the rails as shown. Do not rush this stage as it easy to destroy the point by getting it too hot. My approach was to wrap as much of the point as I could in wet kitchen paper and to allow the rail to cool completely between soldering each joint. The three wires give you access to the track power (red and black) and the vee (white) and can be wired directly into most accessory switches found on point motors. If you don't need access to the track power (i.e. you are feeding the accessory switch from a power bus) then you can remove the left over black and red wires just leaving the bridges between the switch and stock rails.

Step 4

The final step is to electrically isolate the frog and vee from the switch rails. Use a small piercing saw to cut the rails just to the right (when viewed from below) of the sixth sleeper. If you can avoid cutting the webbing then the point will be stronger but I found this impossible with the saw I used. The point can now be connected to the rest of the track not forgetting that you will need to use isolated rail joiners on at least the two vee rails to avoid a short circuit.

When viewed from the top the changes appear minor and the wires can easily be dropped through holes in the baseboard out of sight. The main advantage, as discussed earlier, is that the point can now be painted and ballasted without worrying about retaining a clean contact surface for the switch rails as they are always at the same polarity as the accompanying stock rail.

I'm not going to go into the issue of wiring the point up as this has been covered elsewhere (a quick search for DCC friendly point wiring will set you on the right track) and can be done in a number of different ways depending on the switches etc. you want to use. At some point I'll wire these up to the Cobalt-S lever and have the power switched over at the same time as the servo moving the point, but I know some people will prefer using a micro-switch activated by the moving tie bar etc. Whichever option you choose if you've followed these steps, and not destroyed the point (I killed at least three before I got this worked out) then you should never have an electrical contact issue ever again!

In theory the PECO points can be used straight from the packet, but from prior experience I won't be doing that ever again. The problem is that, as manufactured, the points rely on the contact between the switch and stock rails to provide power. While this works well with a new point as soon as you try and paint, weather, or ballast the track it is exceedingly likely that the point of contact will be obscured and the power flow will either stop entirely or be very temperamental. On Jerusalem, I had no end of problems with the one scenic point and no amount of careful cleaning would give me a reliable point. The solution to this is to perform a small amount of surgery on the point so that we no longer rely on the contact between the rails to transfer the power.

Before we start altering the point we need to ensure some consistent terminology so that the instructions are clear. So here we have an annotated photo of a right hand PECO crazy track OO9 point.

Now that we are all on the same page here are four simple steps to upgrade the point.

Step 1

Counting from the vee end of the point, use a small razor saw to remove the webbing from under the inner vee rails between the first and second sleepers and also the webbing from under all four rails between sleepers six and seven (helpfully these are the sleepers with writing on the bottom). Be careful not to cut into the rails and try and make sure the sleepers don't slide along the rails.

Step 2

Add a small amount of superglue (the runny kind not a gel) at each point indicated in the photo. Capillary action will help draw the glue into the gap between the rails and sleepers and will help to hold the point together. Once the glue has dried use a small file or fibreglass pen to clean the newly exposed rail surfaces.

Step 3

Solder three wires to the rails as shown. Do not rush this stage as it easy to destroy the point by getting it too hot. My approach was to wrap as much of the point as I could in wet kitchen paper and to allow the rail to cool completely between soldering each joint. The three wires give you access to the track power (red and black) and the vee (white) and can be wired directly into most accessory switches found on point motors. If you don't need access to the track power (i.e. you are feeding the accessory switch from a power bus) then you can remove the left over black and red wires just leaving the bridges between the switch and stock rails.

Step 4

The final step is to electrically isolate the frog and vee from the switch rails. Use a small piercing saw to cut the rails just to the right (when viewed from below) of the sixth sleeper. If you can avoid cutting the webbing then the point will be stronger but I found this impossible with the saw I used. The point can now be connected to the rest of the track not forgetting that you will need to use isolated rail joiners on at least the two vee rails to avoid a short circuit.

When viewed from the top the changes appear minor and the wires can easily be dropped through holes in the baseboard out of sight. The main advantage, as discussed earlier, is that the point can now be painted and ballasted without worrying about retaining a clean contact surface for the switch rails as they are always at the same polarity as the accompanying stock rail.

I'm not going to go into the issue of wiring the point up as this has been covered elsewhere (a quick search for DCC friendly point wiring will set you on the right track) and can be done in a number of different ways depending on the switches etc. you want to use. At some point I'll wire these up to the Cobalt-S lever and have the power switched over at the same time as the servo moving the point, but I know some people will prefer using a micro-switch activated by the moving tie bar etc. Whichever option you choose if you've followed these steps, and not destroyed the point (I killed at least three before I got this worked out) then you should never have an electrical contact issue ever again!

Subscribe to:

Comments (Atom)