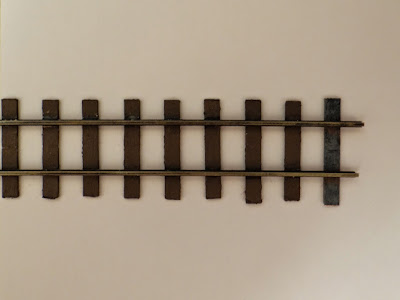

So having settled on an approach to painting sleepers I spent today (on and off while doing other things) finishing off the hand built track for Hudson's Pizza. First job was to fill the gaps in the sleepers with milliput. Pressing a small amount into the gap on each sleeper smoothing it down and removing the excess takes a lot longer than you might imagine and then of course you have to wait for it to harden.

Painting was slightly more fiddly than in the experiments I did because of course the rails are soldered in place and blackened so I needed to keep the paint off them. First up was the white gesso, then a thin wash of RailMatch sleeper grime (50/50 paint and water). I then darkened the sleepers using a black wash which while bring out the details did make things a little too black. This was fixed by dry brushing a little sleeper grime and then a little Model Color brown sand to give a result that I'm really quite happy with.

Saturday, January 24, 2015

Thursday, January 22, 2015

Chemically Blackened

A very short update on the track building today. I spent about ten minutes cleaning the track with a fibreglass pen before chemically blackening the rails and then burnishing the rail top with a wooden coffee stirrer to remove some of the blackening and ensure a good surface for locomotives to collect power. Everything still works and it now looks a bit more prototypical. The sleepers will be next.

Wednesday, January 21, 2015

Sleeper Painting: Experiment Number 3

Having thought about the sleepers a little more I realised that the main problem with the original approach wasn't so much the colour as it was the texture; they were horribly smooth and unnatural looking. After a few suggestions from different people I've come up with what I think is a simple yet effective approach. The sleeper shown here (the furthest right) is painted using the same basic colour as the other sleepers (RailMatch sleeper grime) but with some additional texture.

The trick was to prime the sleepers using some white gesso which provides a textured surface for the paint to stick to. I then thinned the sleeper grime down a little so that it wouldn't obliterate the texture and finished with a quick black wash. This seems to work well giving both texture and some colour variation and is remarkably easy to apply as you don't need to be particularly neat about the painting. With a little extra weathering as the track is bedded into the layout I think it will work well.

The trick was to prime the sleepers using some white gesso which provides a textured surface for the paint to stick to. I then thinned the sleeper grime down a little so that it wouldn't obliterate the texture and finished with a quick black wash. This seems to work well giving both texture and some colour variation and is remarkably easy to apply as you don't need to be particularly neat about the painting. With a little extra weathering as the track is bedded into the layout I think it will work well.

Tuesday, January 20, 2015

Equal Opportunity Modelling

As an equal opportunity modeller I thought I'd allow my other locomotive to experience the new track which gives those who prefer steam locomotives something to watch.

As an equal opportunity modeller I thought I'd allow my other locomotive to experience the new track which gives those who prefer steam locomotives something to watch.Round and Round She Goes, and Where She Stops Nobody Knows

The last time you saw any work on my new layout there was just a new paper track template. Things have moved on quite a bit since then.

Firstly I spent quite a lot of time at the mind numbing task of cutting and then filing a groove into the 90 sleepers required for the layout. I used the same jig as before to help measure and cut the sleepers which definitely makes the job easier although it's still rather boring. The sleepers were then all attached to the template using double sided sticky tape. That is the easy part, next up is the rails.

Obviously the rails needed to be curved into shape before I could try soldering them to the sleepers. Curving them as I went would just have ended in disaster. Now I don't know of anyone who sells a rail bender for OO9 gauge but I bought one from KBscale designed for use with a slightly large rail (their market is 7mm scale modelling). This consists of three sets of washers bolted to a plate. Sliding the rail between the washers introduces a curve into the rail while keeping it flat and not allowing it to twist. I used the tightest setting and it worked perfectly. In fact it produced rails with a curve slightly tighter than I needed.

With the rail nicely curved I soldered on the outside rail first using the template to guide the positioning. I needed two pieces of rail to complete the circle so there are two gaps, one is a nice flush join, the other is a little wider than I would like, but I've now filled it with some solder and filed it back and it seems okay. With the outer rail in place I then soldered the inner rail in place using the excellent rail gauges Paul turned for me. Again two pieces of rail were needed to make the circle but I made a better job of the joints.

Of course having two rails at roughly the right distance apart doesn't mean they will work as track. The only way to know for certain is to add a locomotive and some electricity and see what happens...

I thought I might have to adjust a few tight spots but I couldn't spot any obvious problems so it looks like the track is done (structurally at least, it still needs painting etc.). The video was taken before I filled the over large gap in the outside rail which is what you can hear as the loco passes through the left side of the circle. With the gap filled in the noise is a lot less obvious.

While I was really happy with the short test track, given it was my first attempt at building track, I'm really impressed with how this has come out. I always assumed I'd just be buying track when I built a new layout so I owe a huge thanks to Paul for providing the gauges and everyone who has provided suggestions, advice, and encouragement!

Firstly I spent quite a lot of time at the mind numbing task of cutting and then filing a groove into the 90 sleepers required for the layout. I used the same jig as before to help measure and cut the sleepers which definitely makes the job easier although it's still rather boring. The sleepers were then all attached to the template using double sided sticky tape. That is the easy part, next up is the rails.

Obviously the rails needed to be curved into shape before I could try soldering them to the sleepers. Curving them as I went would just have ended in disaster. Now I don't know of anyone who sells a rail bender for OO9 gauge but I bought one from KBscale designed for use with a slightly large rail (their market is 7mm scale modelling). This consists of three sets of washers bolted to a plate. Sliding the rail between the washers introduces a curve into the rail while keeping it flat and not allowing it to twist. I used the tightest setting and it worked perfectly. In fact it produced rails with a curve slightly tighter than I needed.

With the rail nicely curved I soldered on the outside rail first using the template to guide the positioning. I needed two pieces of rail to complete the circle so there are two gaps, one is a nice flush join, the other is a little wider than I would like, but I've now filled it with some solder and filed it back and it seems okay. With the outer rail in place I then soldered the inner rail in place using the excellent rail gauges Paul turned for me. Again two pieces of rail were needed to make the circle but I made a better job of the joints.

Of course having two rails at roughly the right distance apart doesn't mean they will work as track. The only way to know for certain is to add a locomotive and some electricity and see what happens...

I thought I might have to adjust a few tight spots but I couldn't spot any obvious problems so it looks like the track is done (structurally at least, it still needs painting etc.). The video was taken before I filled the over large gap in the outside rail which is what you can hear as the loco passes through the left side of the circle. With the gap filled in the noise is a lot less obvious.

While I was really happy with the short test track, given it was my first attempt at building track, I'm really impressed with how this has come out. I always assumed I'd just be buying track when I built a new layout so I owe a huge thanks to Paul for providing the gauges and everyone who has provided suggestions, advice, and encouragement!

Sunday, January 18, 2015

Sleeper Painting: Experiment Number 2

Okay that didn't take long. Here we have a rough experiment of painting a metal sleeper. This again follows the same approach I use on the metal parts of the wooden bodied wagons and I've shown some rust where the rails meet the sleepers. I've also included a photo of both approaches for a comparison.

Any thoughts?

Any thoughts?

Sleeper Painting: Experiment Number 1

I'm still trying to clear enough space on my desk to get cracking on Hudson's Pizza but I have now cut and gapped all 90 sleepers I will need for the circle of track.

While I was really happy with how my first attempt at hand built track turned out I've been wondering if I can make it look better and slightly more natural. Specifically I was thinking it might be possible to improve the sleepers. On the test piece I simply painted them with RailMatch sleeper grime. There were two problems with this approach. Firstly there was no texture to the sleeper tops and secondly the colour was very uniform.

What you can see on the left is my first attempt at trying something different. The sleeper isn't soldered to the test track just placed underneath for the photo. Basically I ran a file along the sleeper to add some wood grain and then painted it in roughly the same way I do my small wooden bodied wagons albeit with an extra round of dry brushing using Model Color London Grey to give a slightly more silvery appearance. If I'd painted this in situ then there would have been a bit more variation as it would have been difficult to dry brush right up against the rails. Now I'm not sure I'm entirely happy with the final colour but I'm also finding it difficult to work out if I prefer this to the block colour of the previous attempt. Any thoughts or suggestions?

And before anyone says anything, yes I know Hudson's would likely have used their own metal sleeper track system for the test track, but I'm only basing my layout on it and I think wooden sleepers will be easier to model.... possibly. Maybe I should have a go at doing a metal sleeper?

While I was really happy with how my first attempt at hand built track turned out I've been wondering if I can make it look better and slightly more natural. Specifically I was thinking it might be possible to improve the sleepers. On the test piece I simply painted them with RailMatch sleeper grime. There were two problems with this approach. Firstly there was no texture to the sleeper tops and secondly the colour was very uniform.

What you can see on the left is my first attempt at trying something different. The sleeper isn't soldered to the test track just placed underneath for the photo. Basically I ran a file along the sleeper to add some wood grain and then painted it in roughly the same way I do my small wooden bodied wagons albeit with an extra round of dry brushing using Model Color London Grey to give a slightly more silvery appearance. If I'd painted this in situ then there would have been a bit more variation as it would have been difficult to dry brush right up against the rails. Now I'm not sure I'm entirely happy with the final colour but I'm also finding it difficult to work out if I prefer this to the block colour of the previous attempt. Any thoughts or suggestions?

And before anyone says anything, yes I know Hudson's would likely have used their own metal sleeper track system for the test track, but I'm only basing my layout on it and I think wooden sleepers will be easier to model.... possibly. Maybe I should have a go at doing a metal sleeper?

Saturday, January 17, 2015

Awaiting Dispatch

I've got quite used to the idea of people buying items I've designed. After all I opened Penistone Railway Works just over two years ago and have sold a grand total of 32 items, but because Shapeways handles everything for me I never see the items people order. Designing for Narrow Planet is different as we pack and ship the items people order.

As you may remember the first things I designed as part of Narrow Planet were the L&B roof detailing parts. Within a day of announcing the parts we had a few orders (not surprising really given they started out as a commission) and as you can see the first sets are now all packaged up and ready to post out.

While I was really happy with how the models turned out there is something a little special about seeing them all packaged and ready to go.

As you may remember the first things I designed as part of Narrow Planet were the L&B roof detailing parts. Within a day of announcing the parts we had a few orders (not surprising really given they started out as a commission) and as you can see the first sets are now all packaged up and ready to post out.

While I was really happy with how the models turned out there is something a little special about seeing them all packaged and ready to go.

Friday, January 16, 2015

Hudson-Hunslet Mockup

Given that it will be a while until there is any more progress to show on the Hudson-Hunslet diesel build (I need to update the 3D models and then order some more prints) I thought I'd post a couple more mockup photos to give a slightly better idea how the final model might look; the cabless variety at least. I managed to pull the motor of the chassis so that it would fit into the body again and added a whitemetal driver figure (item number MNV8 from Dart Castings) to give this...

You may notice that a) the driver is held on with blutak and b) he only has one leg! Given I wasn't sure on which figure would be suitable or fit, I designed the chair without the seat cushion pad. The idea being that you'd use a piece of miliput or DAS clay to form the cushion to suit the figure. As for only having one leg, well I was trying to bend the leg of the figure to see if both feet would fit in the footwell when the leg snapped off, and I couldn't be bothered trying to glue it back in place for this mockup.

You may notice that a) the driver is held on with blutak and b) he only has one leg! Given I wasn't sure on which figure would be suitable or fit, I designed the chair without the seat cushion pad. The idea being that you'd use a piece of miliput or DAS clay to form the cushion to suit the figure. As for only having one leg, well I was trying to bend the leg of the figure to see if both feet would fit in the footwell when the leg snapped off, and I couldn't be bothered trying to glue it back in place for this mockup.

Wednesday, January 14, 2015

Supplying the Horse Power

As I mentioned in the previous post the small diesel locomotive needs a chassis and I intend to build this one myself as I couldn't find anything appropriate to use. My approach to this was to 3D print the chassis and then add the gears, wheels, and a motor that I mentioned in another previous post.

The first decsion to be made is what material to use for the chassis? Mostly I print in the Frosted Ultra Detail (FUD) material from Shapeways as I need the fine detail this material allows for. With the chassis though I'm more interested in making it robust than detailed so I ordered my Mk 1 design in black strong and flexible and black detail as well as FUD. That order represents increasing price and decreasing strength and so if the black strong and flexible material works I'll get the best of both worlds.

Due to the different printing tolerances of the three materials the first job was to check that the chassis actually fitted within the body. Interestingly the FUD print doesn't fit at all. The saddle section where the motor will sit is too wide for the gap in the footplate. I find this very odd given that it should be the most accurate dimension wise. Anyway FUD is the most expensive and weakest material so I'm fine with it ruling itself out of contention. Both the black chassis (ordering the dyed versions seemed sensible to avoid having to get paint near the wheels and motor) fitted perfectly so I moved on to trying to assemble the strong and flexible version.

My preference for using the strong and flexible material is that as well as being the cheapest option it should be the most hard wearing. My hope is that I can get away without bearings and just let the parts run freely in the chassis without it wearing away. I deliberately made the holes in the print the same size as the parts (it's easy to remove material, but impossible to add it back), so I started by reaming out the holes for the axles and layshaft. Once I had what seemed like reasonable clearances I assembled the parts. This was very fiddly and time consuming. Most of the problems came from me not reaming out parts far enough but mainly dealing with the pulling a wheel off each axle and then refitting it. I guess I need a wheel puller and press; any suggestion on where or which model to get would be most appreciated. Anyway after battling away for a little while I ended up with this.

As you can see turning the layshaft by hand turns the wheels nicely. I did make a couple of mistakes though. Firstly I should have opened up the holes a little more, as it ended up requiring quite a bit of force to turn the layshaft. Secondly I managed not to keep the worm gears at the ends of the chassis which means the layshaft moves when changing direction before the wheels start to turn. For a first attempt though I think it proves the general design.

Unfortunately from this point on it was one disaster after another. First I added the main pulley to the layshaft and in an attempt to stop the worm gears moving pushed it up to the chassis. This had the desired affect but made the layshaft even harder to turn. I then realised that given the pulley location I'd need to push the pulley on the motor as far down it's shaft as possible. Doing this I managed to drive the shaft through the plastic back plate of the motor. Ooops! Amazingly the motor still rotates under power. Even then I had to offset the motor from the designed position to make the pulleys match up at which point the combined chassis no longer fits in the body. And to top it all off the motor can't provide enough torque to turn the tight drive shaft.

This was attempt number 1 though so I'm not too disheartened by the outcome. I've proved that the general layout seems to work and that I can use the black strong and flexible plastic which should allow me to avoid using bearings. I also now know that I could do with making a few adjustments to the body as well to give a little extra clearance in a few places. Altogether I'm happy with the progress.

The first decsion to be made is what material to use for the chassis? Mostly I print in the Frosted Ultra Detail (FUD) material from Shapeways as I need the fine detail this material allows for. With the chassis though I'm more interested in making it robust than detailed so I ordered my Mk 1 design in black strong and flexible and black detail as well as FUD. That order represents increasing price and decreasing strength and so if the black strong and flexible material works I'll get the best of both worlds.

Due to the different printing tolerances of the three materials the first job was to check that the chassis actually fitted within the body. Interestingly the FUD print doesn't fit at all. The saddle section where the motor will sit is too wide for the gap in the footplate. I find this very odd given that it should be the most accurate dimension wise. Anyway FUD is the most expensive and weakest material so I'm fine with it ruling itself out of contention. Both the black chassis (ordering the dyed versions seemed sensible to avoid having to get paint near the wheels and motor) fitted perfectly so I moved on to trying to assemble the strong and flexible version.

My preference for using the strong and flexible material is that as well as being the cheapest option it should be the most hard wearing. My hope is that I can get away without bearings and just let the parts run freely in the chassis without it wearing away. I deliberately made the holes in the print the same size as the parts (it's easy to remove material, but impossible to add it back), so I started by reaming out the holes for the axles and layshaft. Once I had what seemed like reasonable clearances I assembled the parts. This was very fiddly and time consuming. Most of the problems came from me not reaming out parts far enough but mainly dealing with the pulling a wheel off each axle and then refitting it. I guess I need a wheel puller and press; any suggestion on where or which model to get would be most appreciated. Anyway after battling away for a little while I ended up with this.

As you can see turning the layshaft by hand turns the wheels nicely. I did make a couple of mistakes though. Firstly I should have opened up the holes a little more, as it ended up requiring quite a bit of force to turn the layshaft. Secondly I managed not to keep the worm gears at the ends of the chassis which means the layshaft moves when changing direction before the wheels start to turn. For a first attempt though I think it proves the general design.

Unfortunately from this point on it was one disaster after another. First I added the main pulley to the layshaft and in an attempt to stop the worm gears moving pushed it up to the chassis. This had the desired affect but made the layshaft even harder to turn. I then realised that given the pulley location I'd need to push the pulley on the motor as far down it's shaft as possible. Doing this I managed to drive the shaft through the plastic back plate of the motor. Ooops! Amazingly the motor still rotates under power. Even then I had to offset the motor from the designed position to make the pulleys match up at which point the combined chassis no longer fits in the body. And to top it all off the motor can't provide enough torque to turn the tight drive shaft.

This was attempt number 1 though so I'm not too disheartened by the outcome. I've proved that the general layout seems to work and that I can use the black strong and flexible plastic which should allow me to avoid using bearings. I also now know that I could do with making a few adjustments to the body as well to give a little extra clearance in a few places. Altogether I'm happy with the progress.

Twenty-Four (Frosted Ultra Detail) Horses

Yesterday saw the arrival of yet another delivery from Shapeways. It was a nice large box so contains fodder for a number of posts, but I thought I'd start by showing you all the body for the Hudson-Hunslet 24HP diesel locomotive the render of which you've seen a few posts ago.

I'm really happy with how it has turned out. There are a few stepping lines on some of the large surfaces, but as there is no rivet detail this should be easy to clean up. Of course the body still needs quite a few parts before it is complete but these will be etched parts and I've yet to draw these up. I'm hoping I can use the same body with different etched parts to build a few different variants but we will have to see how that goes.

I was actually slightly surprised as to just how small the model is. I don't know why it surprised me; with a wheelbase of just 2' 10" (which scales out to 11.3mm) it was never going to be huge, but holding it brings home just how tiny it is. Next step will be to sort out a powered chassis for it. There were parts for this in the same order but I'm going to build the suspense and make you wait for another post to see how successful that is (hint, I don't know as I haven't built it yet).

I'm really happy with how it has turned out. There are a few stepping lines on some of the large surfaces, but as there is no rivet detail this should be easy to clean up. Of course the body still needs quite a few parts before it is complete but these will be etched parts and I've yet to draw these up. I'm hoping I can use the same body with different etched parts to build a few different variants but we will have to see how that goes.

I was actually slightly surprised as to just how small the model is. I don't know why it surprised me; with a wheelbase of just 2' 10" (which scales out to 11.3mm) it was never going to be huge, but holding it brings home just how tiny it is. Next step will be to sort out a powered chassis for it. There were parts for this in the same order but I'm going to build the suspense and make you wait for another post to see how successful that is (hint, I don't know as I haven't built it yet).

Friday, January 9, 2015

Pizza Track Template: Take 2

Another day, another track template. After posting about the track template yesterday I took another look at it and realised I'd messed up. The template consists of four pieces of paper stuck together and I initially thought that the white space at the edges of the sheet was intentional so cut them off before joining the sections to give a single template. Unfortunately that wasn't the case and cutting of the paper meant the circle wasn't completely circular. You can see this in the join at the front in the photo from yesterday.

I also decided that I'd probably got the sleepers a little too close together on the original template, so rather than just reprinting I've generated a new template with only 90 sleepers (down on the 120 sleepers on yesterday's attempt). I think this looks better and given how tedious and time consuming cutting the sleepers is I think it's a good decision.

I also decided that I'd probably got the sleepers a little too close together on the original template, so rather than just reprinting I've generated a new template with only 90 sleepers (down on the 120 sleepers on yesterday's attempt). I think this looks better and given how tedious and time consuming cutting the sleepers is I think it's a good decision.

Thursday, January 8, 2015

Pizza Track Template

As my modelling area starts to reappear from under the detritus of Christmas I've made a small start on my new Hudons's Pizza layout; I've designed and printed the track template.

The next job will be to cut the 120 sleepers required for the full circle before I can think of doing any actual track laying. This time I'll also remember to gap the sleepers before soldering on the rails, especially as it will be much harder to do afterwards on a circle of track than it was on the straight test piece I built before.

The next job will be to cut the 120 sleepers required for the full circle before I can think of doing any actual track laying. This time I'll also remember to gap the sleepers before soldering on the rails, especially as it will be much harder to do afterwards on a circle of track than it was on the straight test piece I built before.

Subscribe to:

Comments (Atom)